Case Studies

2023.05.10 up

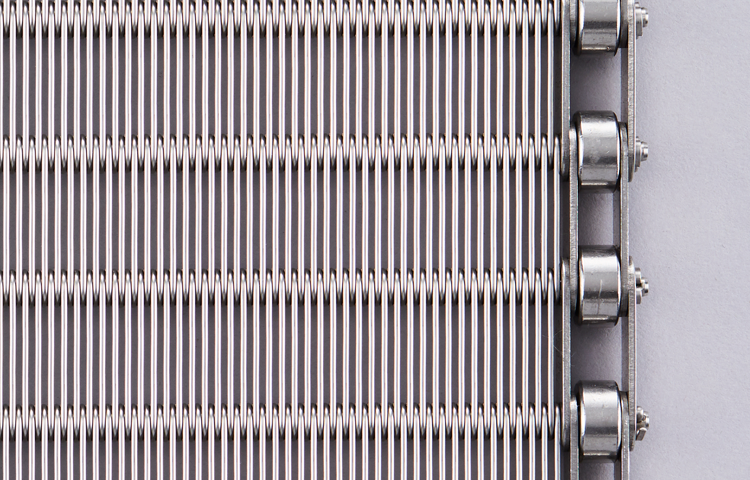

Product fall prevention by changing specifications of mesh belts with chains (F2 → R2)

By changing the mesh of the mesh belt with a chain to a smaller specification than the conventional product, it was possible to prevent falls during transport.

Customer Issue

The wide mesh of the belt leads to the fall of the product.

Semicircular products (automobile products) were transported on the belt.

A width of the semi-circular product is supported by only one point of a spiral pitch and it is not stable during transportation. It leads to fall down during transportation.

Our proposal

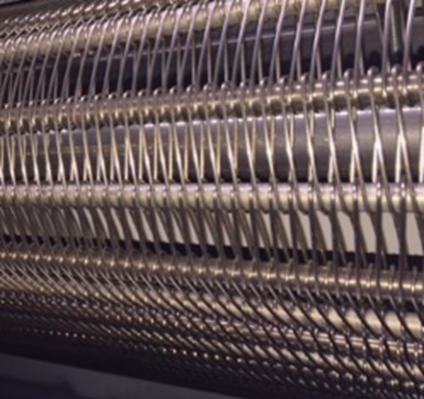

Reduce the mesh of the belt (F2 → R2)

Product width: Lasen pitch of conventional F2 belt for about 10mm: 7.2mm and 1 point support, Lasen pitch: Changed to support two points by making R2 of 4mm.

From the support of one lasen, the fall measures were taken by using two.

Effect after introduction

The fall of the product was significantly reduced, leading to the reduction of labor.

By changing the specifications of the belt, the product fell almost completely.

As a result, it was no longer necessary to allocate personnel standing on the transport exit side, which led to labor saving.

Products used this time

- Wire Conveyor Belt

- Sprocket drive (with chain)

- Food

- Chemical

- Beverage

- Automotive

- Electronic Parts

- Pharmaceutical

- Building Material

- Machine

- Oil

- Civil Engineering

- Steel

- Non-Woven Fabric

- Fiber

- Environmental

- Metal Parts

- Water Treatment

- Mining

- Heating

- Cooling

- Conveying

- Washing

- Dehydration

- Fryer

- Dryer

- Steamer

- Heat Treatment