Products

BEKIPOR®

- Filter

- Filter

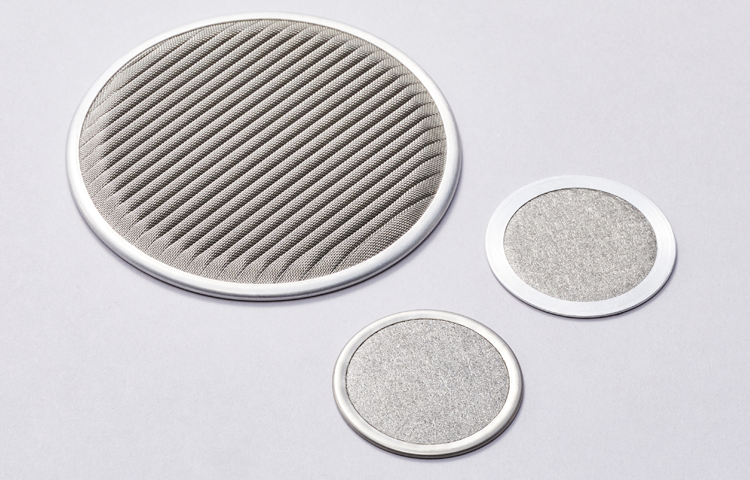

- Disk Filter

- Rectanglar Filter

- Disk Filter

- Pleated Filter

- Food

- Chemical

- Beverage

- Electronic Parts

- Non-Woven Fabric

- Fiber

- Pharmaceutical

- Automotive

- Machine

- Oil

- Filtration

- Strainer

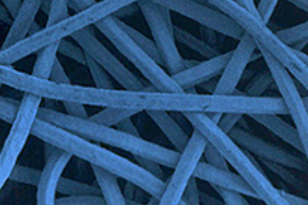

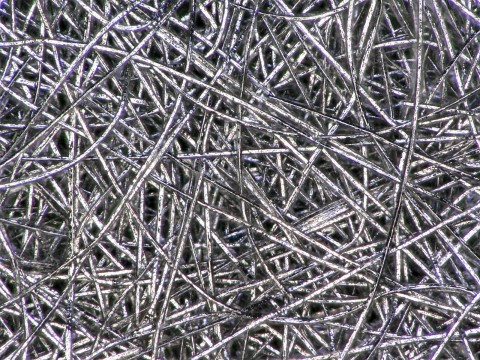

BEKIPOR® is a non-woven sintered medium of ultra-fine fibers.

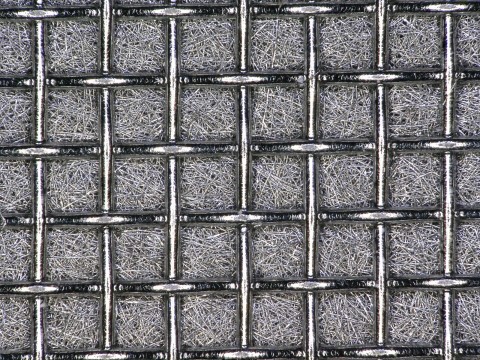

While wire mesh is used as surface filtlation, it's used as depth filter because it has internal filtlation structure.

Characteristics

・Since the porosity is high, it gets low pressure drop, high collection efficiency and long filtration lifetime, compared with the other filter medium.

・Since it has complex three-dimensional structure of fine fibers, it can be used not only for foreign particles collection but also for gel separation.

・It can be used under high temperature and high pressure.

・It's excellent in corrosion resistance.

・It can be reused repeatedly after backwashing, ultrasonic cleaning, chemical cleaning, or pyrolysis.

This is a filter media which enables energy-saving and high-speed filtlation.

BEKIPOR® is a trademark of N.V.BEKAERT S.A.

Products

-

ST-AL3

AL3 is the most standard type and ranging from 3μm to 75μm of filter rating. Because it's depth filtration media, it can be used for gel separation in polymer filtration. -

ST-CL3

Because of the high porosity, it has high dirt holding capacity. It shows high performance under relatively low pressure condition, such as monomer filtlation before polymerazation. -

ST-CL4

It does not get deformed easily even under high fluid pressure, because of the compressive resistance. Therefore, it ensures filtration lifetime of filters used under high pressure difference such as spin pack filter and central polymer filter. -

ST-DL4

It is same as CL4 in terms of compressive resistance but it is superior to CL4 in terms of mechanical strength and collection efficiency. It is suitable for spinpack filters especially for leaf disc filters. Furthermore, it's superior to the others in terms of reuseability because of its excellent durability. -

Support Mesh

It is possiblet to sinter together with S-mesh: φ0.125 x 48mesh for reinforcement.

・S type Reinforcement on one side

・SS Type: Reinforcement on both sides

・Others K-mesh (φ0.25 x 40mesh), N-esh (φ0.19 x 30mesh) -

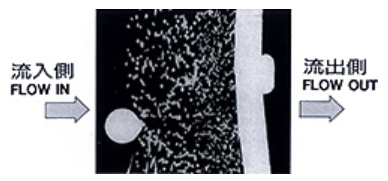

It is expected that filteration lifetime will be extended by flowing in liquid from coarser fiber side (marked "FLOW IN") to the other side. On the other hand, in case of gas filters ,having pulse jet washing, or backwashing filters in liquid filtlation, it can be washed more efficiently by flow-in from the fine fiber side because fine particle cakes are formed on the surface of the filter medium.

We can accommodate custom orders!

There are a wide variety of industrial wire mesh depending on customer's application and operating conditions. Our products are made to order in cooperation with each department to meet customer needs.

From hearings to support after delivery, we provide the optimal products that customers demand through an integrated system.

About this product