About Us

Manufacturing processes

We manufacture hi-quality products can be used with confidence according to standards set for each product.

Kansai Wire Netting manufactures products through its quality management system for customers to use without worry. Most of products are "custom-made" and we produce a wide variety of high-quality products with the accumulation of technologies and unique production facilities that can shape any needs.

Example of Wire Conveyor Belt Manufacturing Process

Wires are processed into rods and spirals to assemble belt and weld edges. Stretching process to control straightness of belt and degreasing process are available as an option. Belt will be shipped after inspection.

-

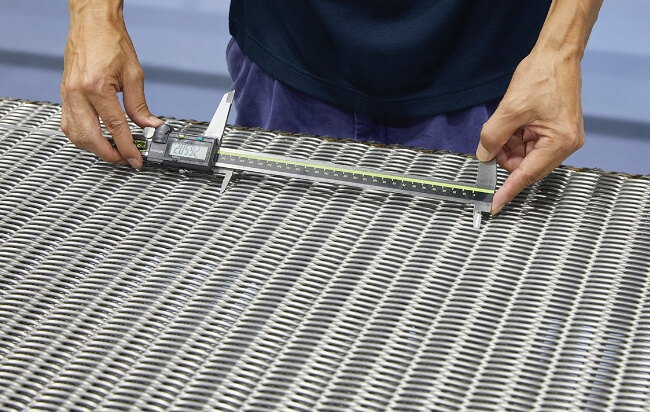

1Material inspection

Measure wire diameter and check other properties before using.

-

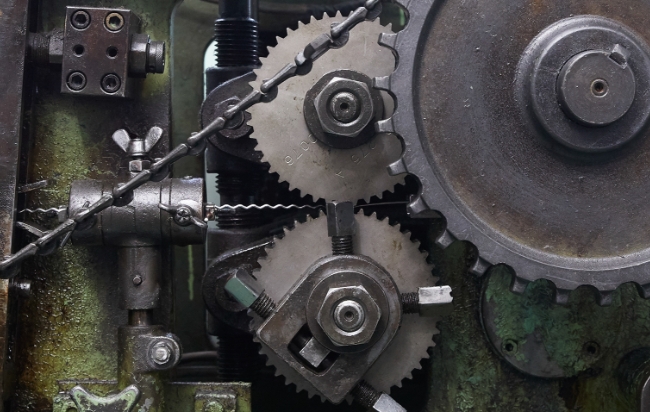

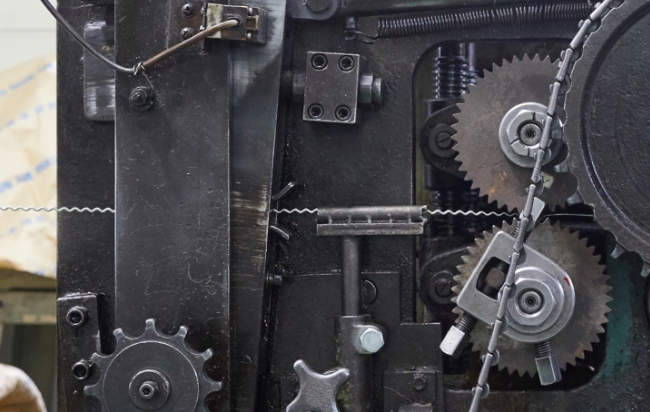

2Rod processing

Use gears to cirmp wire.

-

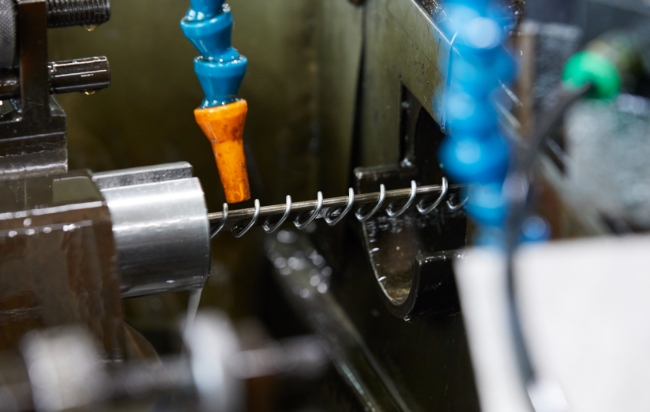

3Spiral processing

Spiral wires are processed using special jigs.

-

4Embedded

The spirals of right wound and left wound are alternately arranged and connected by rods.

-

5Welding processing

Weld rod end and spiral end at belt edge.

-

OptionStretching processing

By rearranging a part of belt, left and right length of belt are adjusted to make sure belt will run straightly.

-

OptionDegreasing processing

Neutral detergent removes processed oil.

-

6Product Inspection

Inspections are conducted in process at each process, but final inspections are performed before shipment.

Example of Screen Manufacturing Process

Wire is crimped and woven on weaving loom. After finish weaving, wire mesh is processed to have hook strips ( which is necessary to install mesh on vibrating sieve machine )and mesh ends are finished to stop fraying. Then, it is shipped after inspection.

-

1Material inspection

Measure wire diameter and check other properties before using.

-

2Material processing

Use gears to cirmp wire.

-

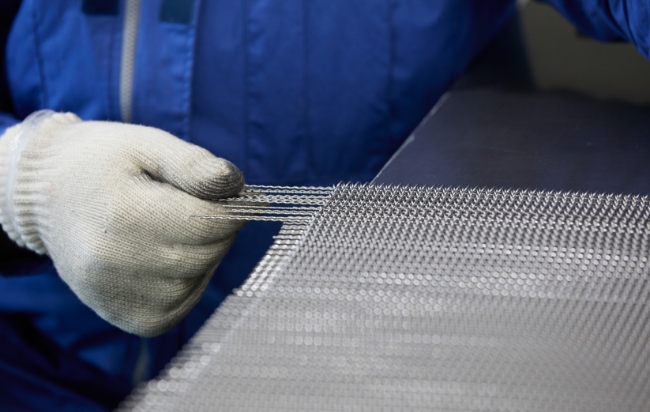

3Weave processing

Pre-crimped wires are arranged as warp wires and other pre-crimped wires are inserted as weft wires on weaving loom.

-

4Finishing process

Wire mesh is processed for hook strip and edge is finished to stop fraying so that wire does not come off from end of wire mesh.

-

5Additional processing

If necessary, hook strip is fixed by riveting and silicon rubber or EVA is used to protect or reinforce a part of wire mesh.

-

6Final inspection

Inspections are conducted in process at each process, but final inspections are performed before shipment.