About Us

Evaluation test

We have established an inspection system to ensure quality.

There is a large number of inspection and testing facilities exclusively for wire mesh. We conduct qualitative and quantitative inspections and evaluations to ensure product quality. Evaluation test is also possible individually upon request from customers.

Test machines

-

Wire conveyor belt ruuning test machine

Evaluates running stablity and durability of conveyor belt. In addition to photos, there are test machines of various sizes and layouts.

-

Vibratory sieving test machine

The sieving test is performed using a circular vibration sieve machine to evaluate sieving speed, sieving efficiency, separation particle size, etc.

-

Air permeability test appratus

It passes air through filter media to evaluate the relationship between flow velocity and pressure drop, and detemines visous resistance coefficient, inertial resistance coefficient and ventilation in filter media.

-

Glass bead test apparatus

Diluted slurry is flitered to evaluate filter media filter rating ( separation particle size ) from particle size distribution efore and after the filtration.

-

Bubble point test appratus

Compressed air is sent to the filter media filled with liquid above, and the maximum hole diameter of filter media is evaluated from the air pressure when a bubble occurs from the filter media surface.

-

Tensile testing machine/compression testing machine

We evaluate tensile strength of wire mesh and wire, and compression characteristics of wire mesh formed products. Various grab jigs are available to accommodate various types of wire mesh.

-

Horizontal tensile testing machine

It is a tensile testing machine for large loads and mainly used to evaluate tensile strength of conveyor belts.

-

Flexion fatigue testing machine

The wire mesh is repeatedly bent under a certain level of tension, and the durability of the wire mesh against bending fatigue is evaluated by the number of times until it is broken.

Measuring instruments

-

Tension meter

It will evaluate tension on wire mesh. The above picture is for screen, but there is also tension meter for conveyor belt.

-

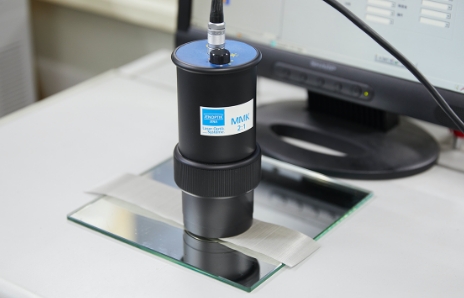

Image measurement sysmtem for wire mesh

Acquire enlarged images of woven wire mesh and automatically measure wire diameter and aperture size by image analysis.

-

Microscope

It is used for magnified observation for wire, wire mesh and wire mesh related parts. Investigate damage, cleanliness and scrtaches on wire mesh.

-

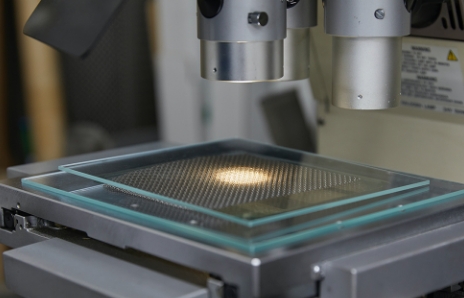

Profile projector

Wire diameter and aperture size are measured from enlarged projected image of woven wire mesh.

-

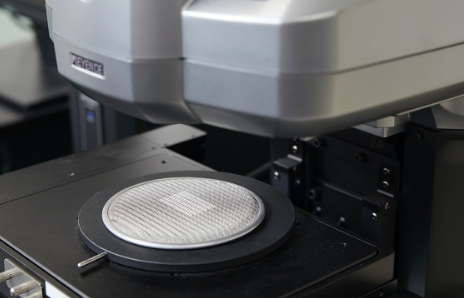

3D optical profilometer

The 3D shape is acquired by applying light to wire mesh and wire mesh-related parts, and three-dimensional observation and dimension measurement are performed.

Numerical analysis

-

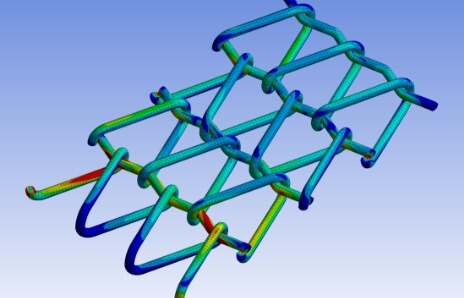

Structural Analysis

3D model of wire mesh or wire mesh related parts is created using 3D CAD and so on. Structural analysis is performed to evaluate deformation behavior and geneated stress. It is used for product design and development.

-

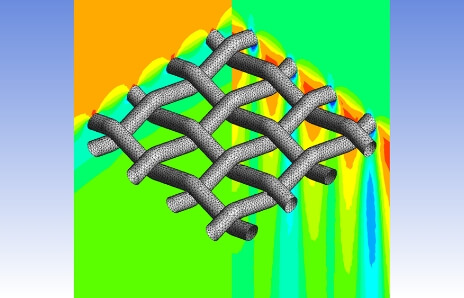

Fluid Flow Analysis

3D CAD, etc. creates 3D model for filter media and filter, and performs fluid flow analysis to evaluate state of flow passing through them. It is used for product design and development.