Case Studies

2025.11.12 up

Material change and periodic inspection of heat-resistant belts

Selecting highly oxidant materials, proposing and implementing field tests. In addition, periodic inspections are conducted to observe changes over time, and the survey results are reported.

Customer Issue

Occursion of oxidation scale and deterioration of belts

Existing materials have a large amount of oxidation scale generated, causing problems that adhere to products.

Yes. In addition, as oxidation progresses, the belt deteriorates and breaks partially.

It was connected.

Our proposal

We perform material change and field tests and report the situation through periodic inspections.

We select highly oxidant materials and propose field tests.

In addition, periodic inspections are conducted to observe changes over time, and the survey results are reported to customers each time.

Effect after introduction

Change to optimal material and solve problems

Periodic inspections have made clear changes over time for each material due to oxidation.

I was able to determine the best material.

By changing the material, oxidation was suppressed, and the trouble of belt breaking due to deterioration was eliminated.

As a result, it was possible to extend the life of the belt for an average of two months.

Products used this time

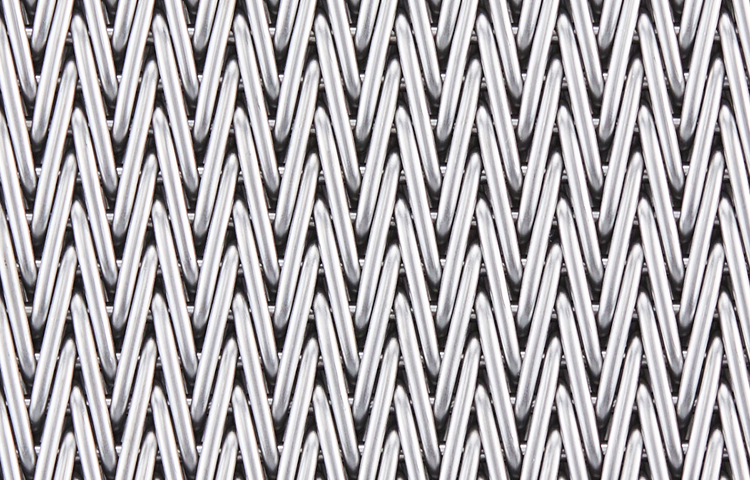

- Wire Conveyor Belt

- Friction drive

- Food

- Chemical

- Automotive

- Electronic Parts

- Pharmaceutical

- Building Material

- Machine

- Oil

- Steel

- Non-Woven Fabric

- Metal Parts

- Water Treatment

- Mining

- Heating

- Cooling

- Heat Treatment

- Conveying

- Washing

- Dehydration

- Dryer

- Steamer