Technical Information

Design of PLANET PLAFLON

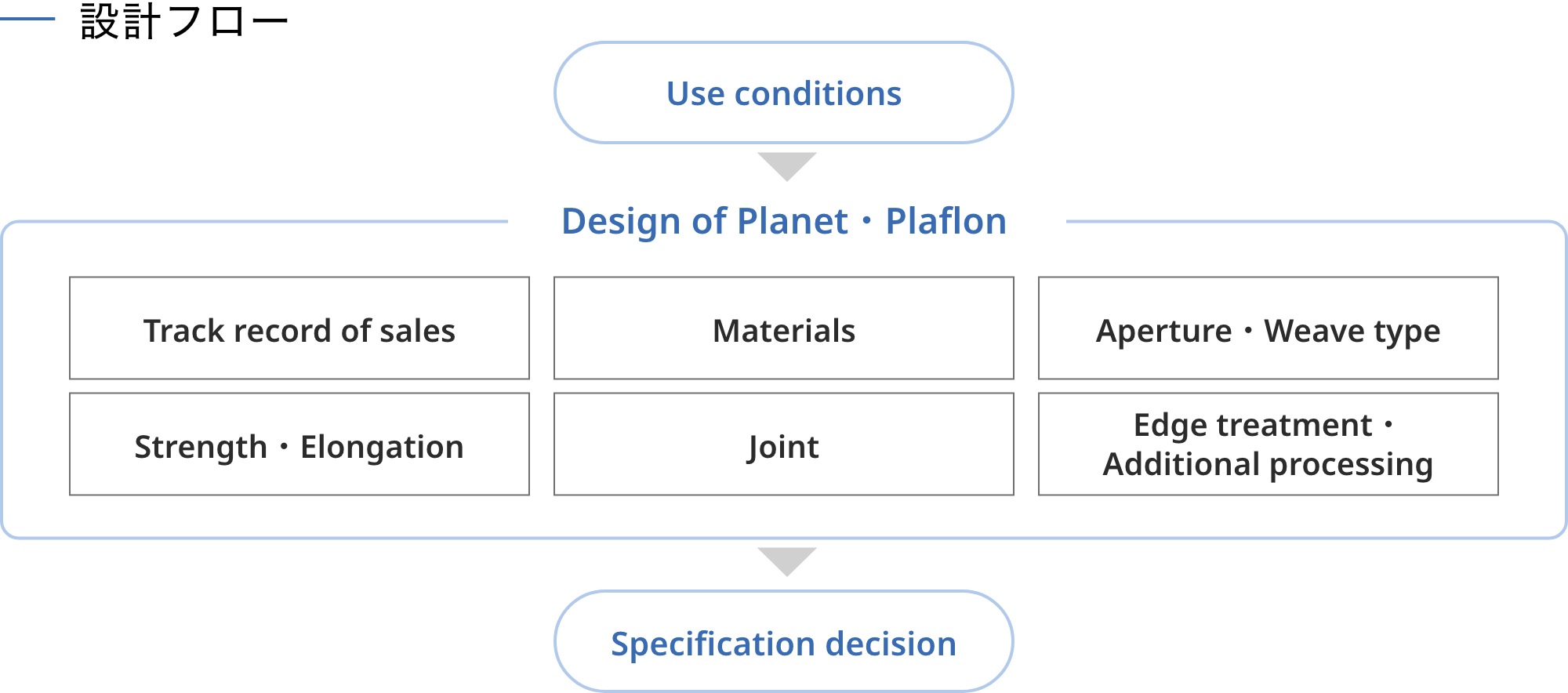

Design Flow

In Kansai Wire Netting Co.,Ltd., we propose the best PLANET PLAFLON based on your terms of use.

Design Flow

| Operating Conditions | Check the transport conditions, operating conditions, and layout of the Conveyor equipment (including widthPLAFLON and length) in processes that are already in use. |

|---|---|

| Experiences | If you are already using Planet PLAFLON or any of our achievements that match the terms of use, we will refer to them. |

| Material | We select materials in consideration of a temperature, a corrosion environment, terms of use, and so on. Depending on the environment to be used, the performance of plastic changes more than that of metal; so selecting materials is very important. |

| Aperture and Weaving | Aperture and Weaving are important factors related to driving stability, tension, wear resistance and joint methods. It is possible to select a mesh and weaving method suitable for the purpose of use. |

| Strength and Elongation | We calculate the strength and elongation of the belt to see if it is suitable for the terms of use. When the belt stretches, we pay attention to production dimensions so that the conveyor device can be tailored enough to maintain the tension. |

| Joint |

If the belt tied in a loop can be attached to the conveyor device, we splice them by weaving. If not, they will be joint by racing. joint/edge processing/additional work of PLANET/PLAFLON |

| Edge processing and additional work |

We will consider ear processing according to usage conditions and Conveyor equipment (ear resin processing to protect and reinforce the edge, etc.) and additional work. joint/edge processing/additional work of PLANET/PLAFLON |

| Determing Specification | Through the above flow, we will determine specifications of PLANET/PLAFLON to meet your requests. |

Comparison of Belt Characteristics ※1

| Plastic wire belt | PLAFLON | Wire Conveyor Belt | ||

|---|---|---|---|---|

| conveying weight ※2 | △ | × | ◎ | |

| High-speed driving | ◎ | △〜○ | × | |

| Heat-resistant ※3 | High temperature | △ | ○ | ◎ |

| Low temperature | ◎ | ◎ | ◎ | |

| moisture resistance | ×〜◎ | ×〜△ | ◎ | |

| Chemical resistance ※3 | Acid | △〜◎ | ×〜△ | ×〜△ |

| Alkaline | △〜◎ | ×〜○ | ○ | |

| Wide range | ◎ | △〜○ | △ | |

| Surface smoothness (approach) | ○〜◎ | △〜○ | ×〜△ | |

- 1 The evaluation varies depending on the usage conditions and specifications, so please refer to it as a guide only.

- 2 The person who can transport heavy objects is highly evaluated. On the other hand, when transporting relatively light materials, the plastic Planet PLAFLON itself is also lightweight, so it may be possible to save energy.

- 3 Please refer to the catalog for heat resistance and chemical resistance.

Highest temperature and chemical resistance of PLANET and PLAFLON

Recommended roll diameter (approximate)

Appropriate roll diameter is required for PLANET and PLAFLON to run stably. The following is a standard roll diameter (excluding support rollers that support a belt).

| Plastic wire belt |

More than 200 times that of warp diameter (when a net thickness is less than twice that of warp diameter) More than 100 times than a net thickness (when the net thickness is more than twice that of warp diameter) |

|

|---|---|---|

| PLAFLON | mesh type sheet type |

More than 150 times than a net thickness More than 100 times than a net thickness |

※The above figures may not be suitable depending on your environment, so please refer to them only.