Technical Information

Joint/Edge processing/Additional processing of PLANET/PLAFLON

Joint

joint method for endless PLANET PLAFLON (mesh type) is shown below. Some items may not be available depending on the size of the aperture or weave type, so please contact us for more information. Sheet-type PLAFLON can be endless by overlapping and welding or using special joint parts.

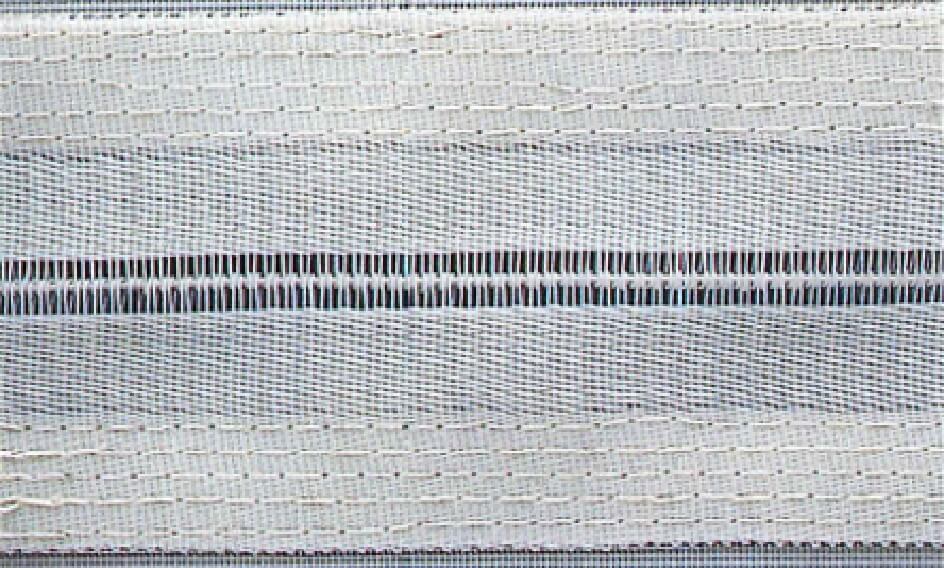

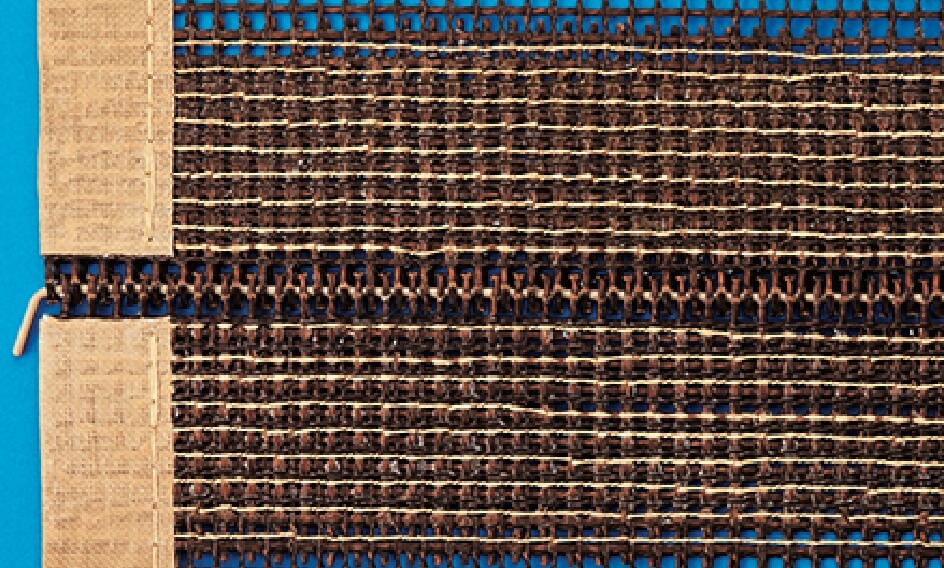

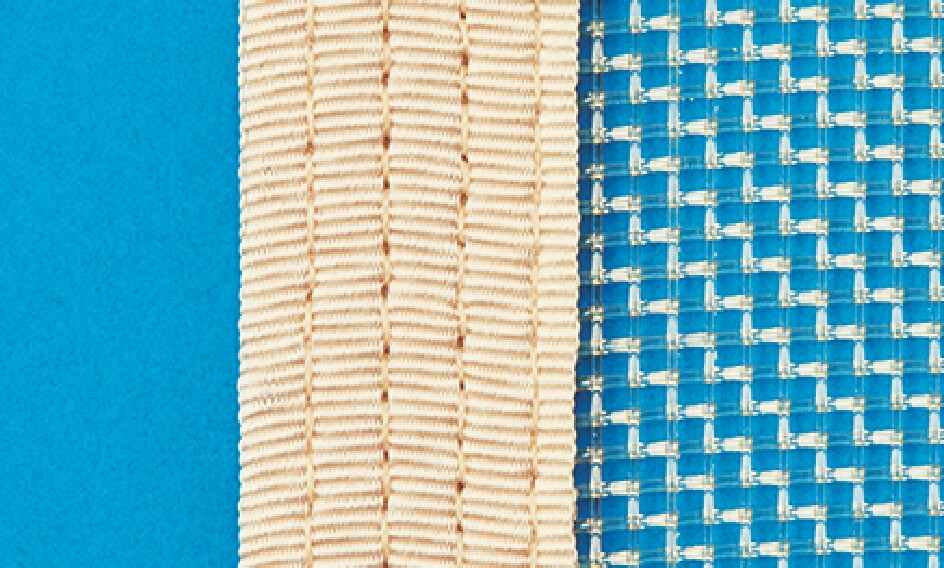

Woven Seam

It is a method of endless by interweaving warp threads. There is little difference between joint and ordinary parts and it offers excellent durability with the least decline in performance at joint area. In the case of coarse aperture, the appearance may differ from the normal part to maintain the strength of the joint part.

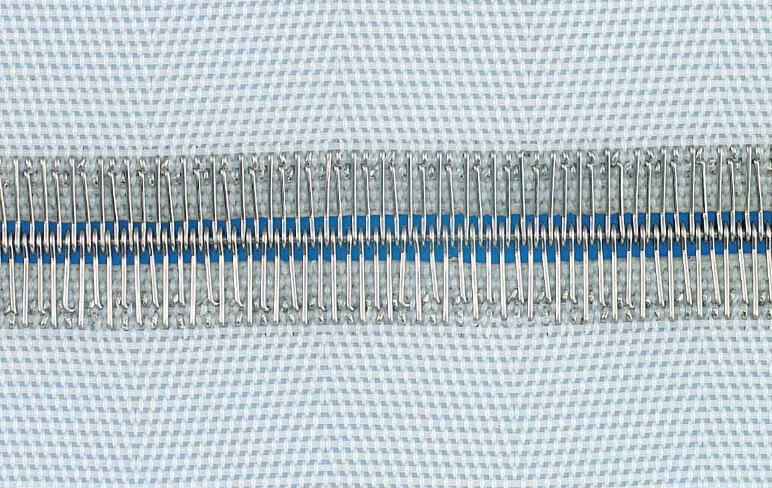

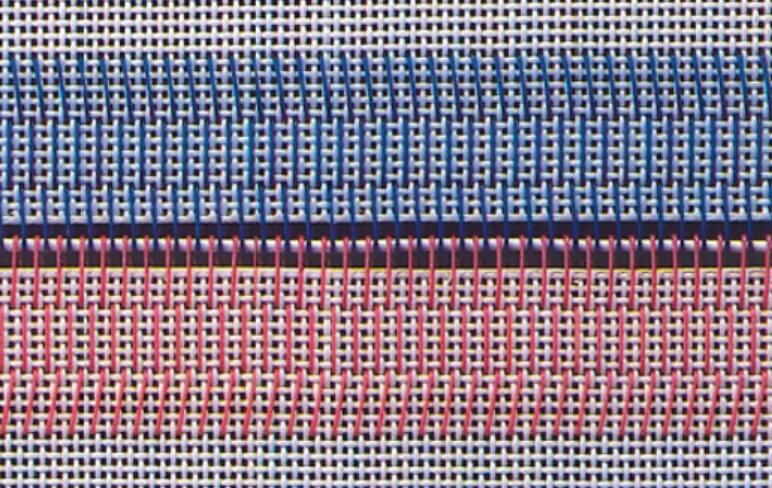

Clipper Lacing

Stainless steel hooks are attached for connecting hooks at the front and rear ends with wire. It is easy to instal and remove net, but the lacing area differs greatly from other ordinary area. It is often used for dehydrators.

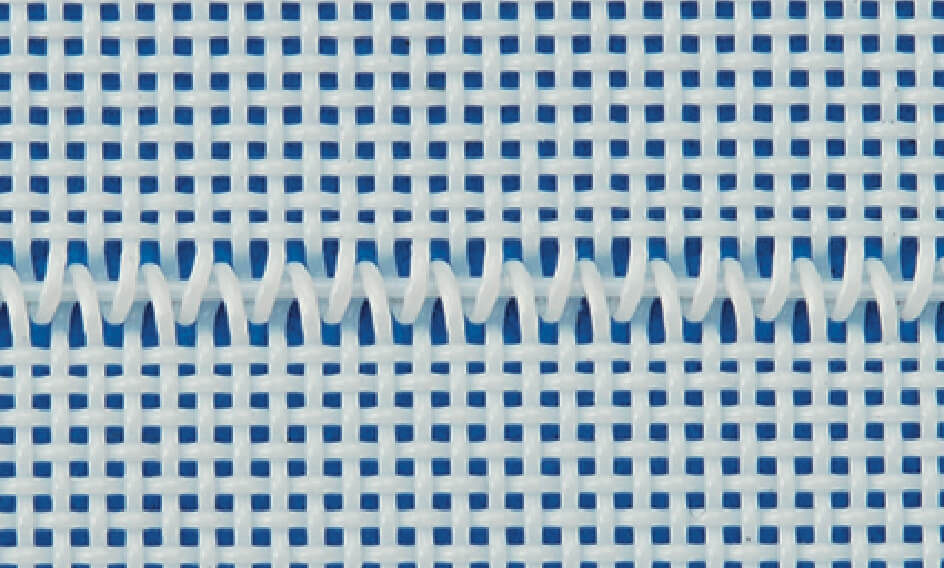

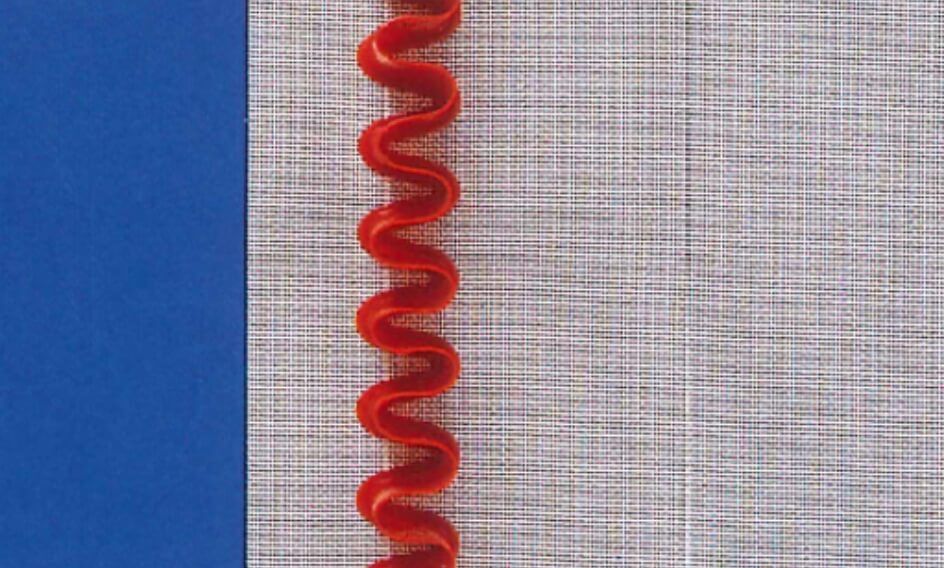

Spiral Lacing

Spiral loops are attached for connecting loops at the front and rear ends with wire. This is used when metal can not be used like clipper lacing.

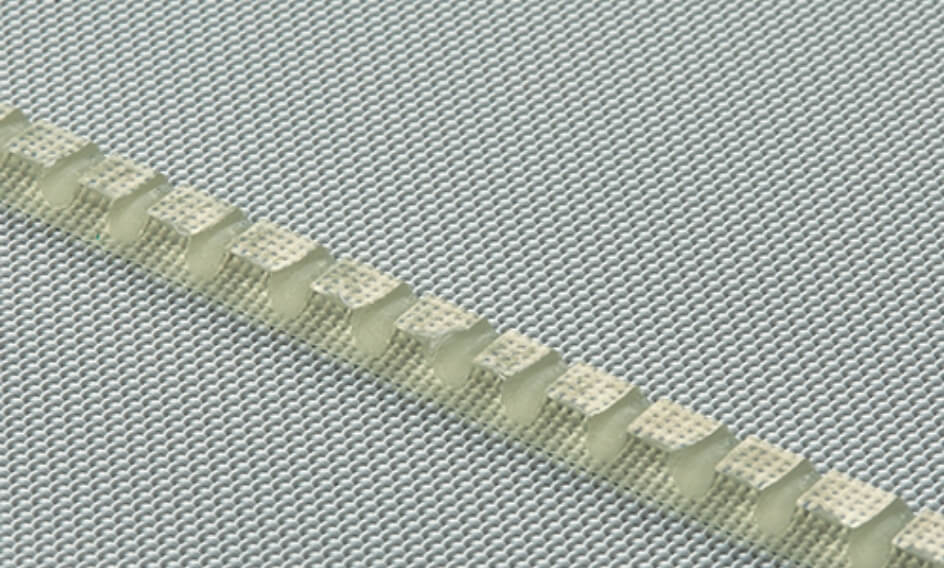

Tape Lacing

This type is made by sewing tapes with loops and mainly used for rotating drum. In case of PLAFLON(mesh type), loops are made by folding back the base fabric and fixed by sewing, then heat sealed.

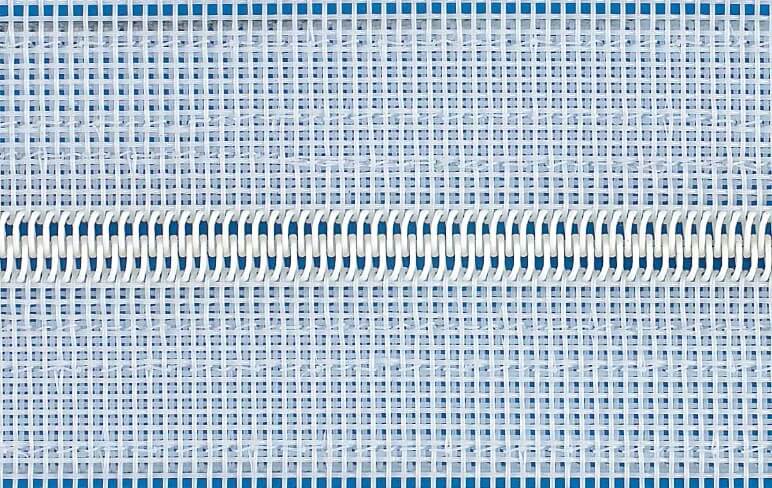

Woven Lacing

Difference betwen joint area and other area is disadvantage of lacing. This joint minimize the difference by applying woven seam technology.

Loop Stitch Lacing

Loops are mady by stitching with special lacing wire. This type withstands high surface pressure and high wear resistance.

Edge processing

Edge treatments for PLANET are shown below.

-

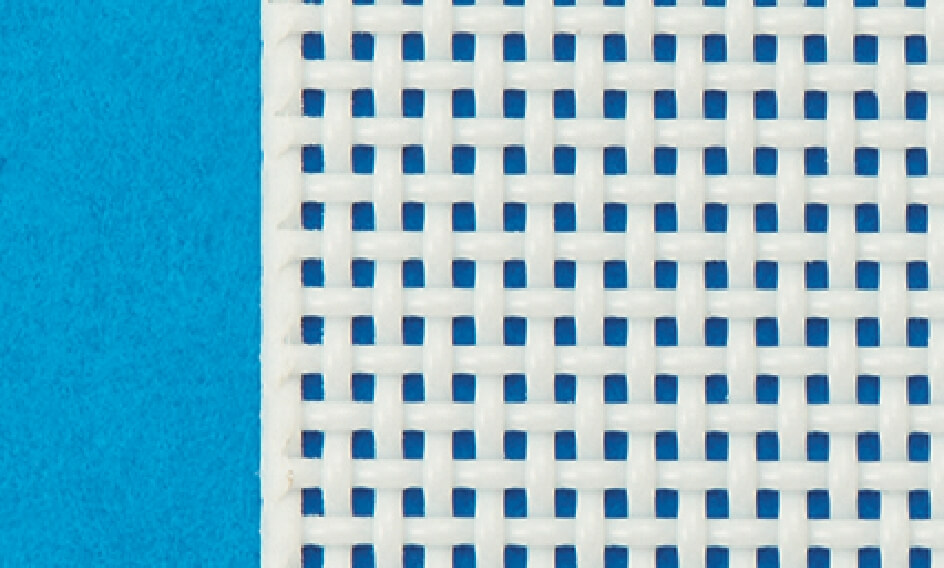

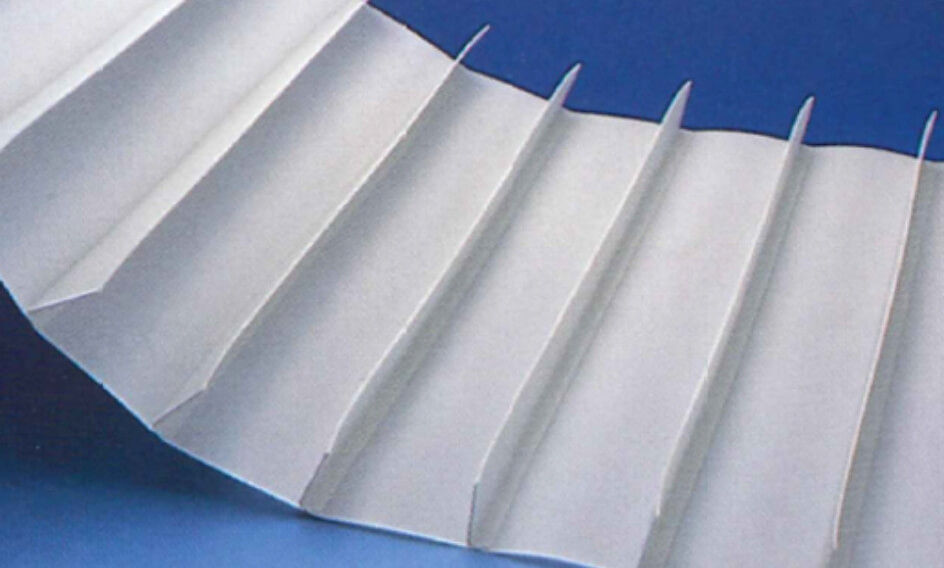

Heat Seal

This is standard treatment for PLANET. Edge is melted by heat and prevent it it from getting frayed.

-

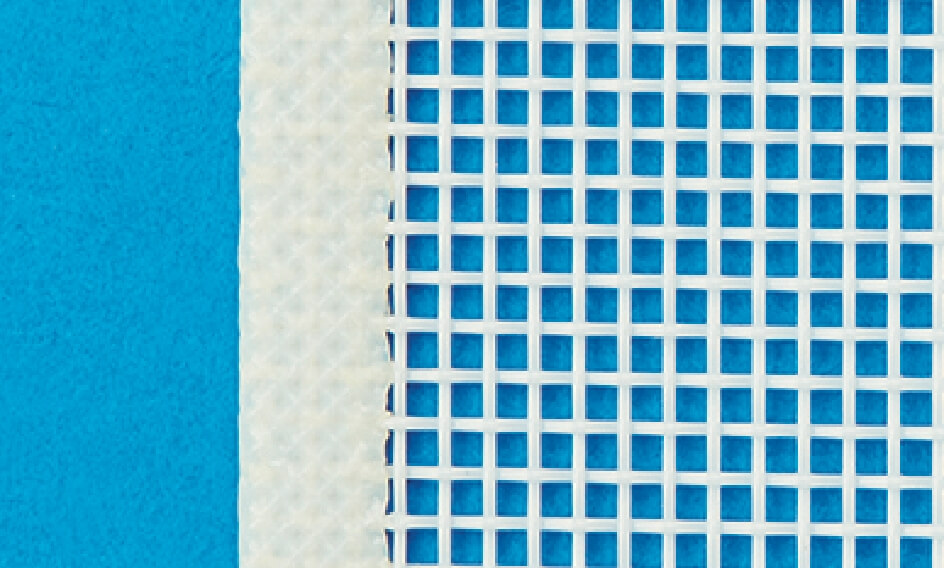

Edge Reinforcement with Coating

After heat seal, another plastic is coated to further reinforce. We use different types of plastic depending on the application.

-

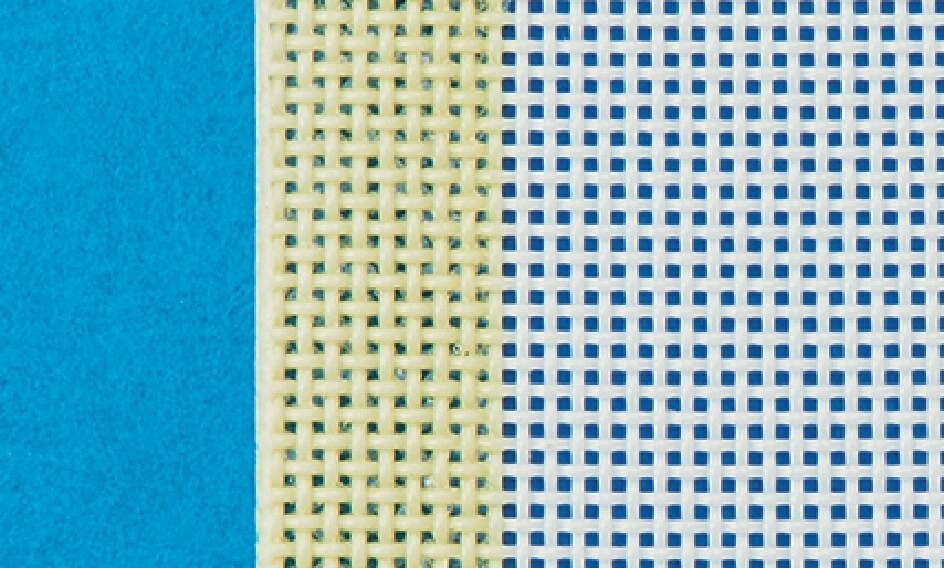

FT Reinforcement/Urethane Reinforcement

Polyester sheet for FT reinforemcnet is weded in the front and back of edge. Urethane sheet is used for Urethane reinforcement.

-

Edge Reinforcement with Cloth

Reinforce by sewing polyester or PPS cloths on edges.

Additional work

Examplels of addtional option of process for PLANET and PLAFLON are as follows.

-

V belt・Stud for Guiding

If meandering adjustment equipment cannot be used, correct operation can be performed by applying V-belt processing and stud processing to the belt. It is also necessary to set up a groove on the roller side.

-

Stopper

Stopper can be attached to prevent products from slipping on a slope conveyor.

-

Side-stopper

Stopper can be attached to edge sides to prevent products from falling off from sides.