Case Studies

2021.11.04 up

Extended lifetime by replacing with Durmalloy

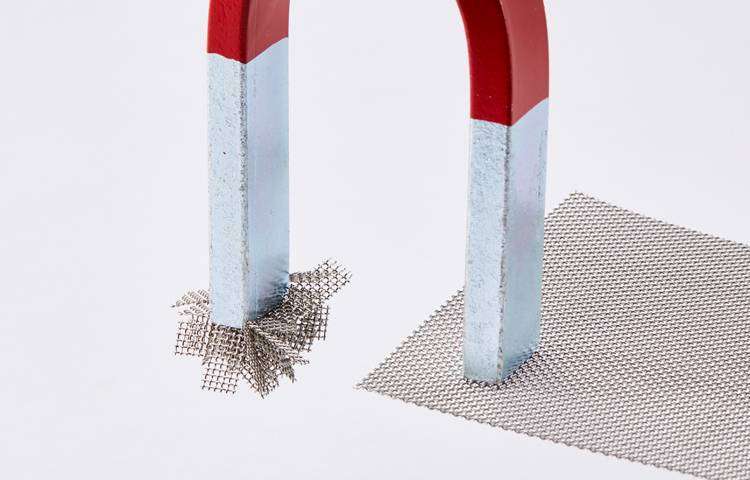

Magnetic wire mesh from other supplier had been used for vibrating screen and the customer had problem of unexpected broken wire to stop production. After repalcing with Durmalloy wire mesh, the problem has been eliminated and planned production becomes possible.

Customer Issue

Wire mesh is damaged early and production is not planned.

One chemical manufacturer used magnetic wire mesh made by other supplier for vibrating screen. The wire mesh was damaged early and it hindered production.

We received a sample of the wire mesh used and examined the mechanical characteristics.

It turned out to be inferior to our Durmalloy.

Our proposal

Trial test with Durmalloy wire mesh

We offered samples of our Durmalloy wire mesh with excellent wear resistance and fatigue resistance. Trial test was performed on actual machine to check the damage status of wire mesh in long term.

Effect after introduction

It is no longer damaged within the replacement cycle.

Former magnetic wire mesh had been damaged in a few days but our Durmalloy wire mesh was not damaged during replacement cycle of 60 days. Production became possible on planned basis.

Products used this time

Magnetic wire mesh (KMG mesh®)

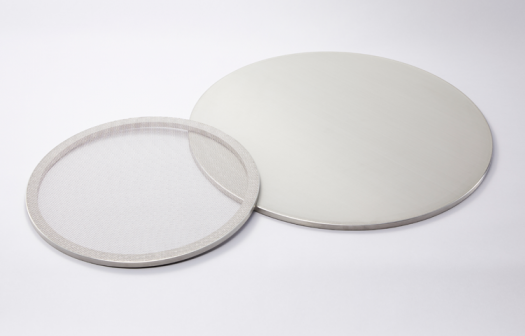

- Filter

- Sieving Screen( metal wire mesh )

- Circular Screen

- Rectanglar Screen

- Food

- Chemical

- Beverage

- Pharmaceutical

- Washing

- Dehydration

- Sieving

- Filtration

- Strainer

- Wire Mesh Basket