Technical Information

Design Flow

Kansai Wire Netting will propose optimal filters based on your usage conditions.

Design Flow

| Operating Conditions | Check the particles, fluids, operating conditions, etc. in the process of introducing or using filter. |

|---|---|

| Experiences | If you are already using filters, or if there is something that matches the usage conditions of our company, we will refer to them. |

| Material | The material is selected in consideration of temperature, corrosion environment, and filter type. For metal filters, SUS304, SUS316, and SUS316L are common. |

| Filter Media Type |

The filter type (type of filter material) is determined based on the purpose and conditions of filtration. Please refer to the product information for detailed features of various filter materials. In addition, an example of comparing performance by type of filter material is summarized below. Examples of Comparison of filter media Characteristics |

| Filter Rating |

The aperture size / porous diameter of filter media is determined based on the required filter rating (size of particles to be separated). To Aperture Size・Open Area Calculation |

| Initial Pressure Drop |

Calculate initial pressure drop of filter media under the operating conditions and confirm that it is below the allowable pressure drop. ※It may not be possible to calculate depending on filter media type and filter shape. To Initial Pressure Drop |

| Tolerance |

Calculate pressure resistance of filter and confirm that filter can withstand the operating conditions. ※It may not be possible to calculate depending on filter media type and filter shape. |

| Filter Shape | By processing the filter material, it is possible to create filter elements in various shapes (circular, square, cylindrical, pleated, cartridge, etc.). We examine filter shape and size suitable for application and filter housing. |

| Determing Specification | After the above design, we will determine the filter specifications that meet your needs. |

Comparison of Filter Meia Charactheristics ※1

| Filter Media Type | Aperture Size Distribution Pore Size Distribution |

Initial Pressure Drop ※2 |

Pressure Resitance | Open Area/Porosity ※3 |

Washing |

|---|---|---|---|---|---|

| Plain Weave・Twilled Weave | ◎ | ◎ | △ | ○ | ○ |

| Plain Dutch Weave・Twilled Dutch Weave | ○ | ○ | ○ | ○ | ○ |

| Sintered Woven Wire Mesh | ○ | △ | ◎ | ○ | ◎ |

| Sintered Non-Woven Fabric of Metal Fiber(Bekipore®) | △ ※4 |

△ | ○ | ◎ | △ |

| Perforated Metal Screen | ◎ | ○ | ◎ | △ | ◎ |

| SCP (Super Clean Plate) | ◎ | ○ | ○ | △ | ◎ |

| Wedge Wire Screen | ◎ | ○ | ◎ | △ | ◎ |

※1 The evaluation varies depending on the specifications of each filter type, so please refer to it as a guide only.

※2 The lower the initial pressure loss, the better the evaluation.

※3 The higher the hole rate/space rate, the better the evaluation.

※4 Vekipores have a wide porous distribution, but since it is an internal filtration (deep filtration) filter, it is characterized by a large amount of foreign matter collected.

We can accommodate custom orders!

There are a wide variety of industrial wire mesh depending on customer's application and operating conditions. Our products are made to order in cooperation with each department to meet customer needs.

From hearings to support after delivery, we provide the optimal products that customers demand through an integrated system.

Filter Rating

When a filter can capture a particle of a certain size larger than a certain amount, the size of that particle is called filtration accuracy.

Generally, absolute filtration accuracy and nominal filtration accuracy are used, and the definition differs depending on the manufacturer. In the case of filtration of liquids, we have absolute filtration accuracy with a particle size of about 95% with partial separation efficiency (also called removal efficiency).

The method of measuring the filtration accuracy varies from manufacturer to manufacturer, so care must be taken when comparing it with the results of other manufacturers. For more information, please contact us.

Calculation for Aperture Size/Open Area

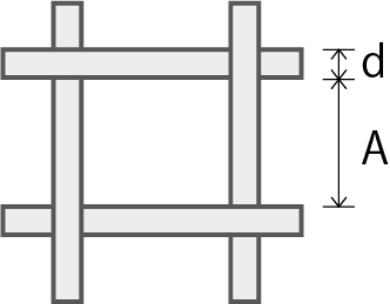

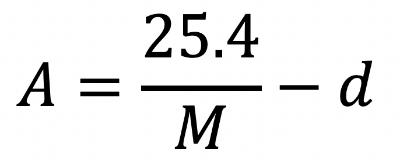

Filter rating does not always match aperture size because it changes according to particle characteristics and filtration conditions, but aperture size is the most important factor. Aperture size of plain weave and twilled weave mesh can be calculated by the following formula.

A: Eye opening [mm] M: Mesh [-] d: Line diameter [mm]

Mesh refers to the number of wire lines or apertures between 1 inch( 25.4 mm ).

From this formula, it can be seen that Plain weave Twilled weave cannot be identified by mesh or aperture size alone, and at least two of wire diameter, Mesh and aperture size are required.

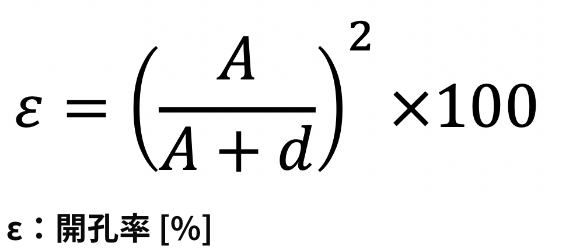

Open area( area ratio of filter media aperture to filter mesia surface ) is calculated by the following formula.

In the same aperture size, the smaller the wire diameter, the higher the open area and the higher the processing capacity, but the lower the pressure resistance. Conversely, if wire diameter is enlarged in the same aperture size, open area will be lower and processing capacity will be lower, but pressure resistance will increase.

The catalog also has a list of specifications that summarize the relationship between Plain weave, Twilled weave's wire diameter, aperture size and open area.

Plain dutch/Twilled dutch weave has a 3-dimensional aperture structure, so calculation of pore size is complicated. If you need pore size calculation, pleae contact us.

Please refer to the product information and catalog for details on the filtration accuracy (nominal filtration accuracy, absolute filtration accuracy) of other filter types, eye opening, and opening rate (opening rate).

In addition to aperture size, initial pressure drop,

If you have any other technical issues or questions,

please do not hesitate to contact us.

Initial Pressure Drop

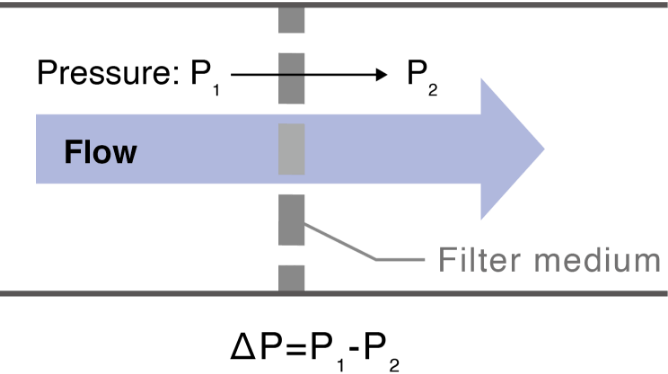

When the fluid passes through filter media, the filter media becomes resistant and causes pressure drop. Pressure loss is an important parameter related to the pressure required for filtration and the filtration life (filter exchange cycle). Initial pressure rop refers to pressure drop only for filter media, which has no clogging or cake( particle layer on the filter media).

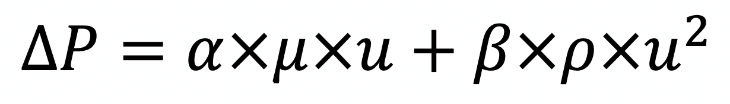

The initial pressure loss of many rods is represented by the following formula (be careful not to mistake the unit).

- ΔP: Pressure Drop [Pa]

- u: flow velocity [m/s] (= flow rate [l/min] ÷ filtration area [cm2] x 1/6)

- α: viscous resistance coefficient [m-1]

- β: inertial resistance coefficient [-]

- μ: viscosity [Pa・s]

- ρ: density [kg/m3]

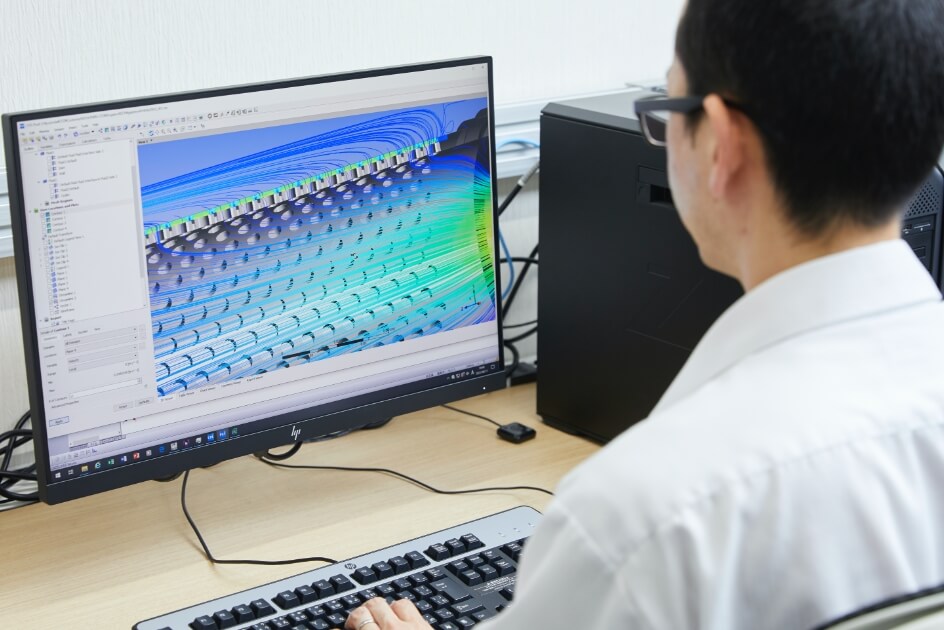

Viscous resitance coefficient α and inertial resitance coefficient β are coefficients unique to filter media and can be obtained by calculation, aier permeability test and fluid flow analysis.

Resistance factor α and β of main types of plain weave, twilled weave, plain dutch weave and twilled dutch weave are listed in the product catalog.

Bekipore®'s resitance coefficient α is also included in the catalog. Bekipore® is mainly used in laminar flow, so inertial resitance coefficient is not considered.

For Zhijin nets and sintered wire mesh (poamets), graphs of pressure loss on air and water (flow rate vs pressure loss) are also included in the catalog.

Filter

Evaluation test

Fiter rating, initial pressure drp and pressure resistance are evaluated as necessary in design and development. Therefore, we have various testing facilities. Fluid flow analysis sometimes assesses filter media's initial pressure drop and fluid flow.