Technical Information

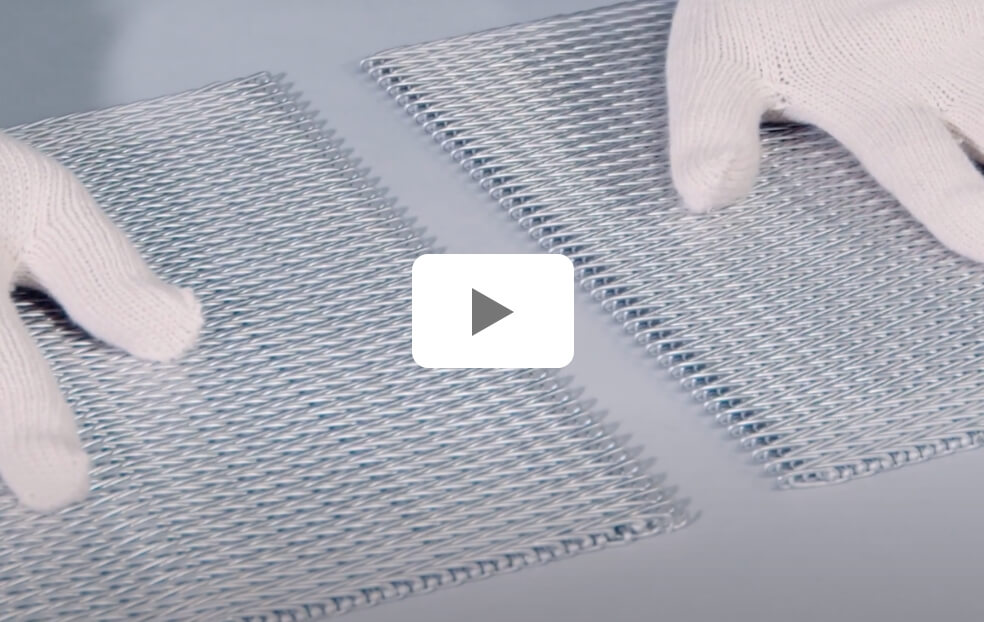

Wire Conveyor Belt Joint

Connecting the ends of the divided belt is called joint.

The joint method differs depending on the belt type. Please refer to the video below for details.

-

K2 type

Left-wound and right-wound spirals are alternately arranged and jointed with the pre-crimped rod. It is common to fix the edge by welding, but there is also a method of clinching( video shows fixing by welding).

-

A4 type

Left wound and right wound spirals are alternatively fit together and connected with three straight rod( two for A3 type). The end is fixed by welding.

-

A4 with Net Flange

The flanges at joint point are bent and flattened, and the ends of each belt are connected with straight rods. The edge is fixed by welding, and finally the flattedned frange is bent back.

-

S type

This type has no rod and inserts one spiral wire while rotating it to spirals of both ends. The edge is fixed by welding or bending.

-

BL type

There is a method of weaving wire formed in a predetermined shape into both ends of wires, and a method of cutting the formed wire and connecting them through joint sleeves( video shows a method of weaving with formed wire ).

-

R1 type

The wire formed in the prescribed shape is entangled with the previous wire and connected. The formed edges of one end are hooked on straight part of the other end and fixed with a special tool.

-

LF2 type

The bod ends of belt are connected by a single rod with one head.

The other side of rod is screwed witout head, and the nut is attached and welded with the rod and link ( belt outside = nut side ).