Technical Information

Wire conveyor belt design

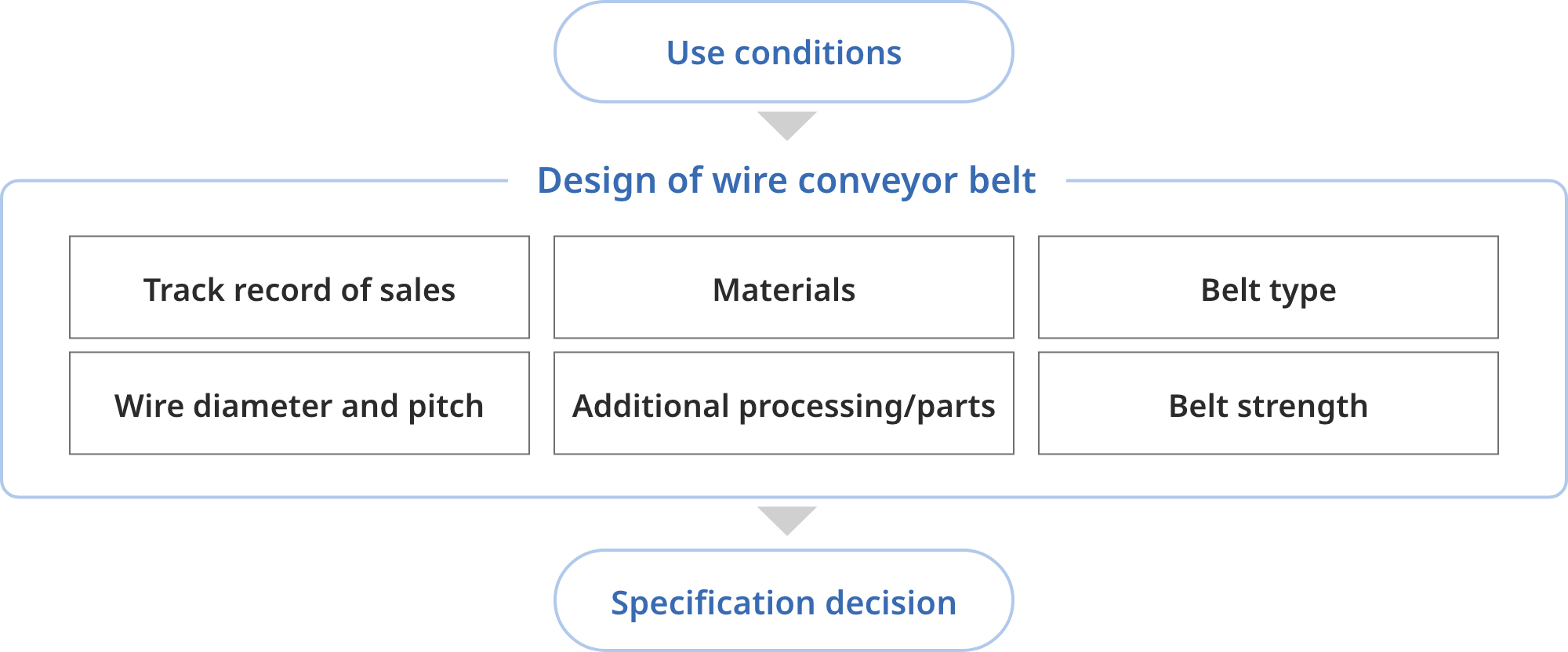

Design Flow

Kansai Wire Netting proposes optimal wire conveyor belts based on the customer's usage conditions.

Design Flow

| Operating Conditions | Confirm the transport conditions and operating conditions of the processes being used, and the layout of the Conveyor equipment (including size such as width and length). |

|---|---|

| Experiences | We will refer to the experience of customer operation on the target line in the past and/or any of our extensive esperience that is matching the operating conditions. |

| Material | Select a material in consideration of temperature, corrosion environmental, etc. (stainless steel, iron, etc.). |

| Belt Type |

It is possible to select the base belt type based on various conditions such as strength, runability, ease of production, and surface characteristics. Please see the product information for details of each belt type. Selection Flow (Example) |

| Wire Diameter・Pitch | Wire diameter and pitch are decided in consideration of operating conditions, belt type and strength. |

| Additional Processing and Parts Examples |

We will consider necessary additional processing and additional parts. Additional processing and parts examples |

| Belt Strength | Check whether the selected belt has sufficient strength against the operating conditions by calculating strength and deflection. |

| Determing Specification | After the above design flow, we will determine the wire conveyor belt specification that meet your needs. |

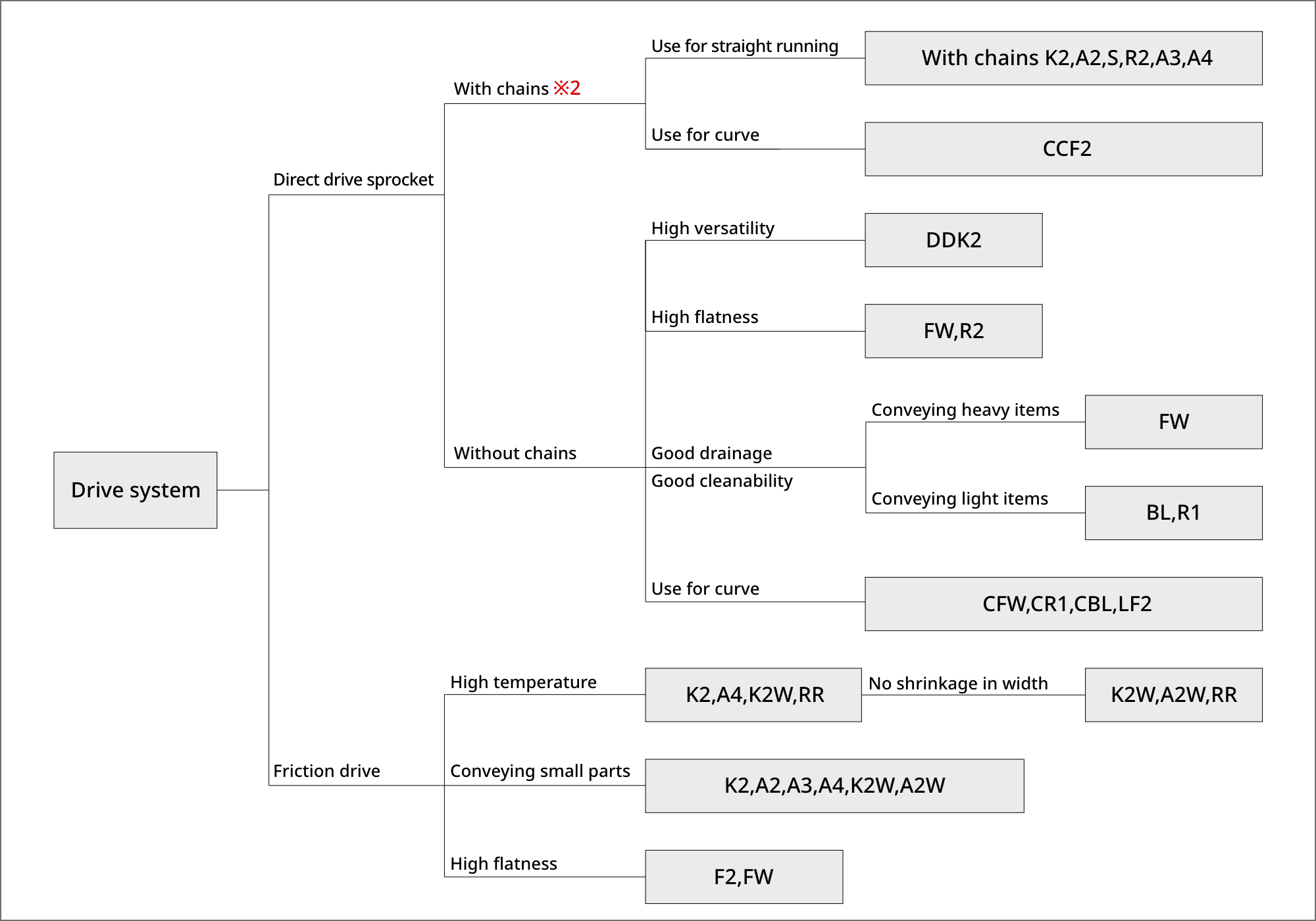

Selection flow of belt type

(Example *1)

※1 This selection flow is an example. It may not fit depending on your operating environmental.

※2 For the characteristics of the wire conveyor belt type used with chains, refer to the characteristics of the flow (e.g., flatness for R2 and F2).

We can accommodate custom orders!

There are a wide variety of industrial wire mesh depending on customer's application and operating conditions. Our products are made to order in cooperation with each department to meet customer needs.

From hearings to support after delivery, we provide the optimal products that customers demand through an integrated system.

Additional Processing and Parts Examples

The following are additional processing and parts for belt.

-

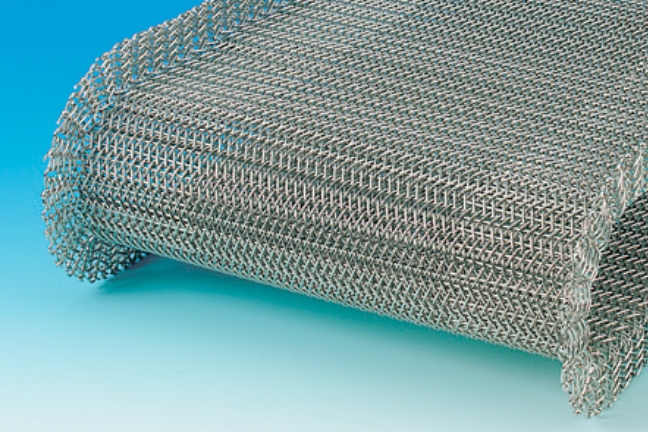

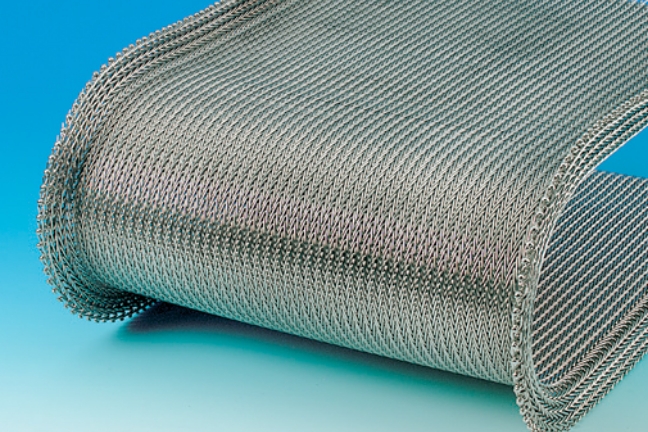

A2W+Net Flange

-

A4+Net Flange

-

A2+Rod Flange

Basically, the belt is used in flat, but in order to prevent the transport from falling off the belt edge, the edge can be turned up as shown in the photo (called net flange ). Please note that the belt type can be used with net flange is limited.

-

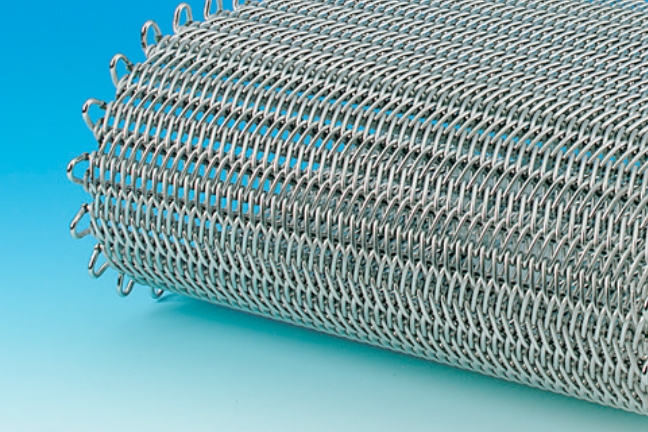

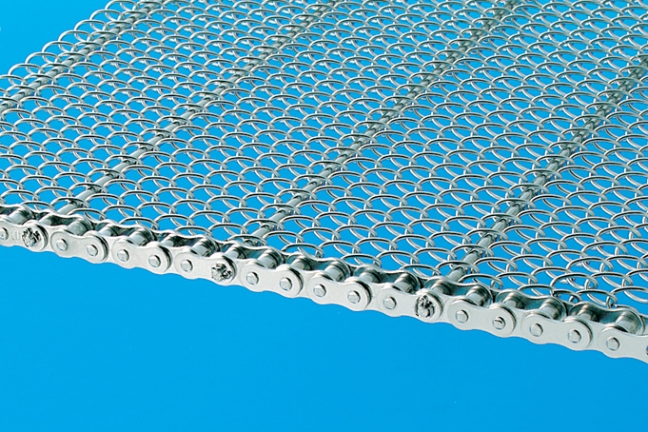

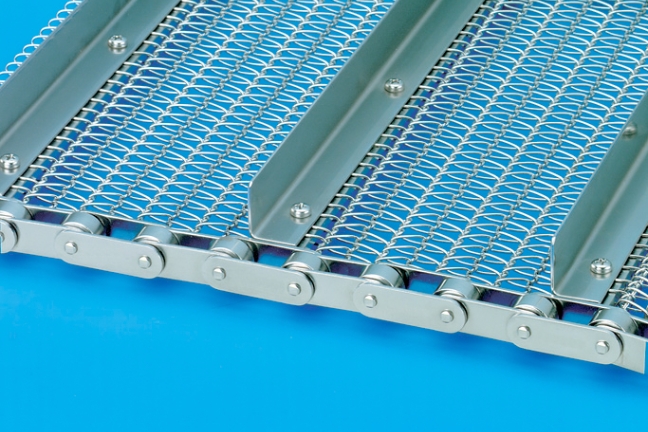

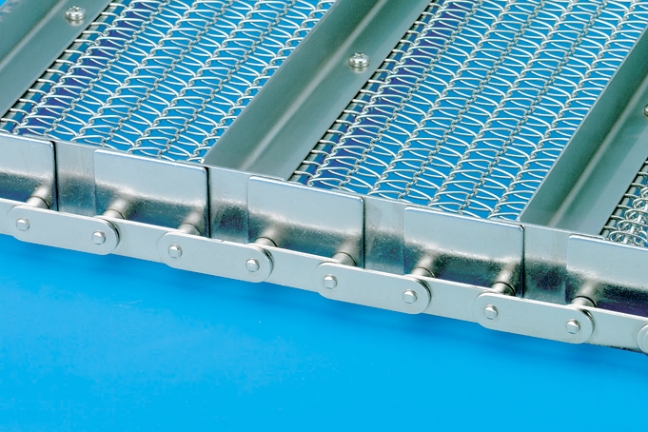

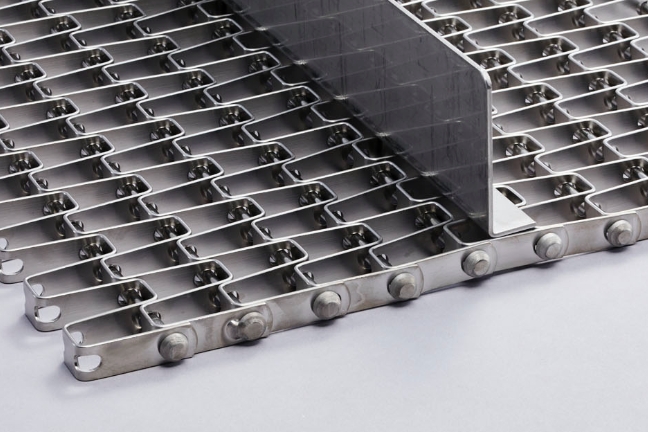

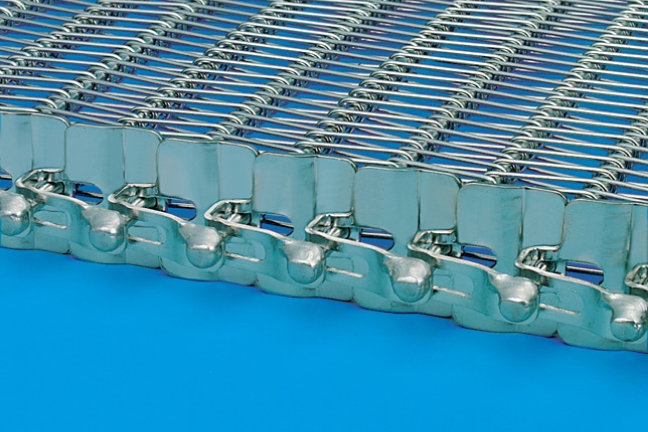

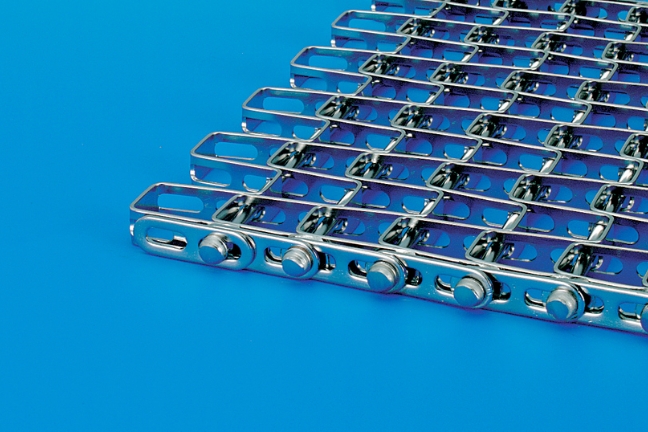

Conveyor Belt with Chain

-

Conveyor Belt with Chain and Stopper

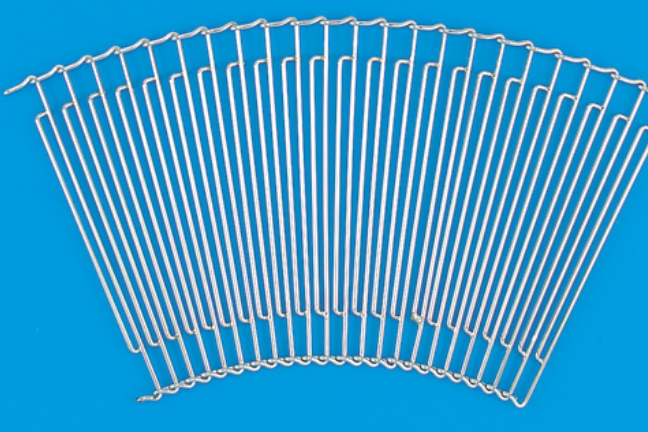

Wire Conveyor Belt

-

Conveyor Belt with Flange Plate, Stopper and Chain

One of the ways to drive the belt with sprocket is to attach chains. There are various types of chains, including not only the size of the chains, but also a flange-type chain with a high chain plate as shown in the photo.

You can also attach a stopper to partition or scrape the transport.

-

DDK2 with Net Stopper

-

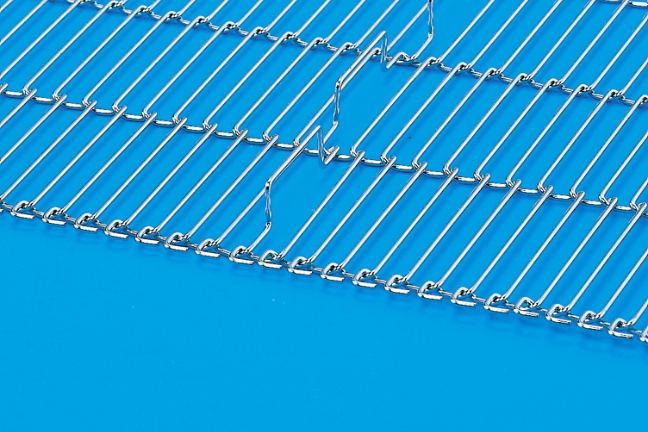

BL with Stopper

-

FW with Stopper

-

LF2 with High Flange Plate Link

-

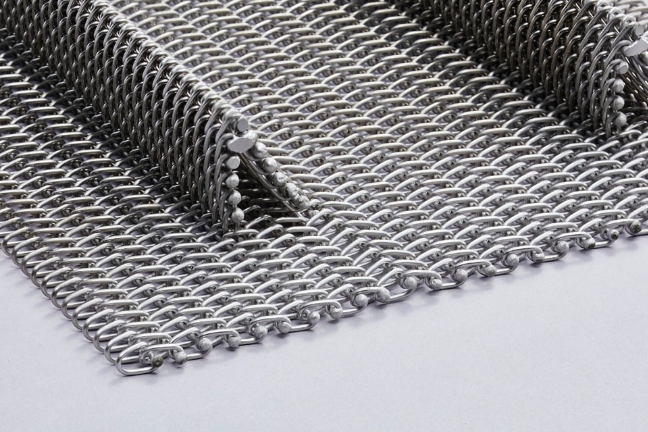

CR1U

-

CFW with Reinforcement Plates

- DDK2 with net as stopper

- LF2 with high flange plate link

- BL to set up its own wire as stopper

- CR1 that includes U-bar to narrow the aperture

- FW with bent angle attached as stopper.

- CF, etc. with reinforced plates for increased strength

There are various other processing results (surface treatment such as fluorinated resin coating is also possible).

Please contact us for more information.

Wire conveyor belt

Evaluation test

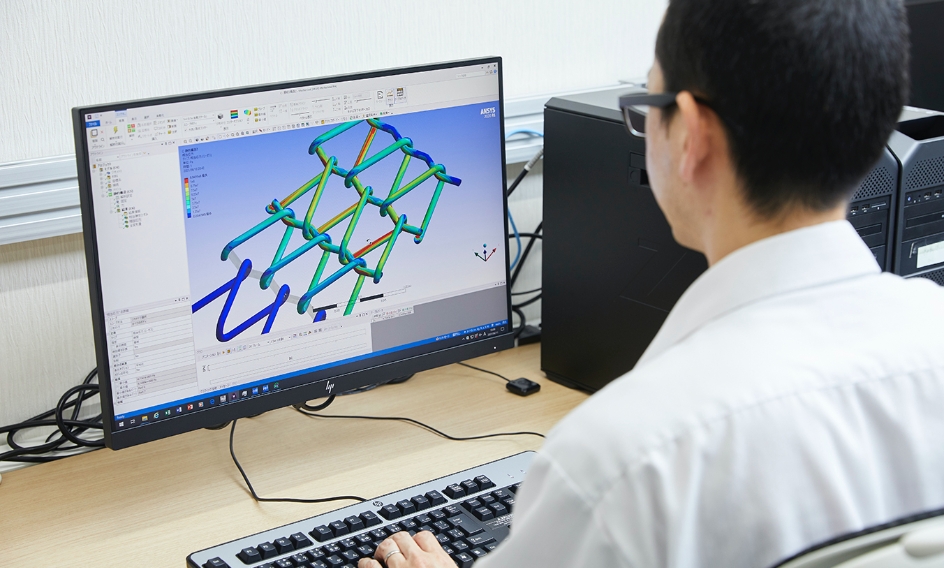

In the design and development of wire conveyor belt, we evaluate driving stability and belt strength as necessary. We have a number of our own conveyor belt test machines. We also conduct structural analysis to evaluate the strength of the details.