Web Showroom

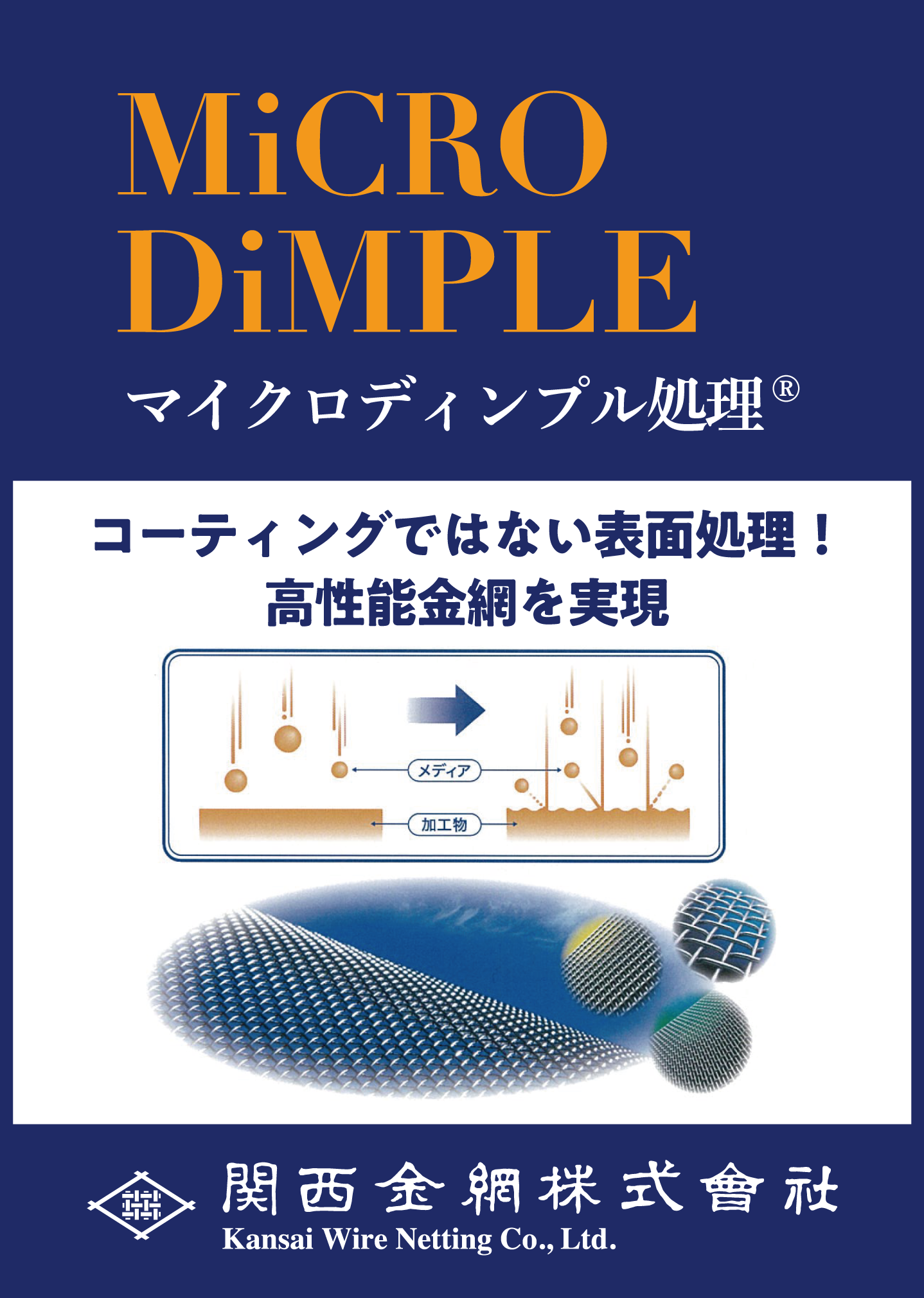

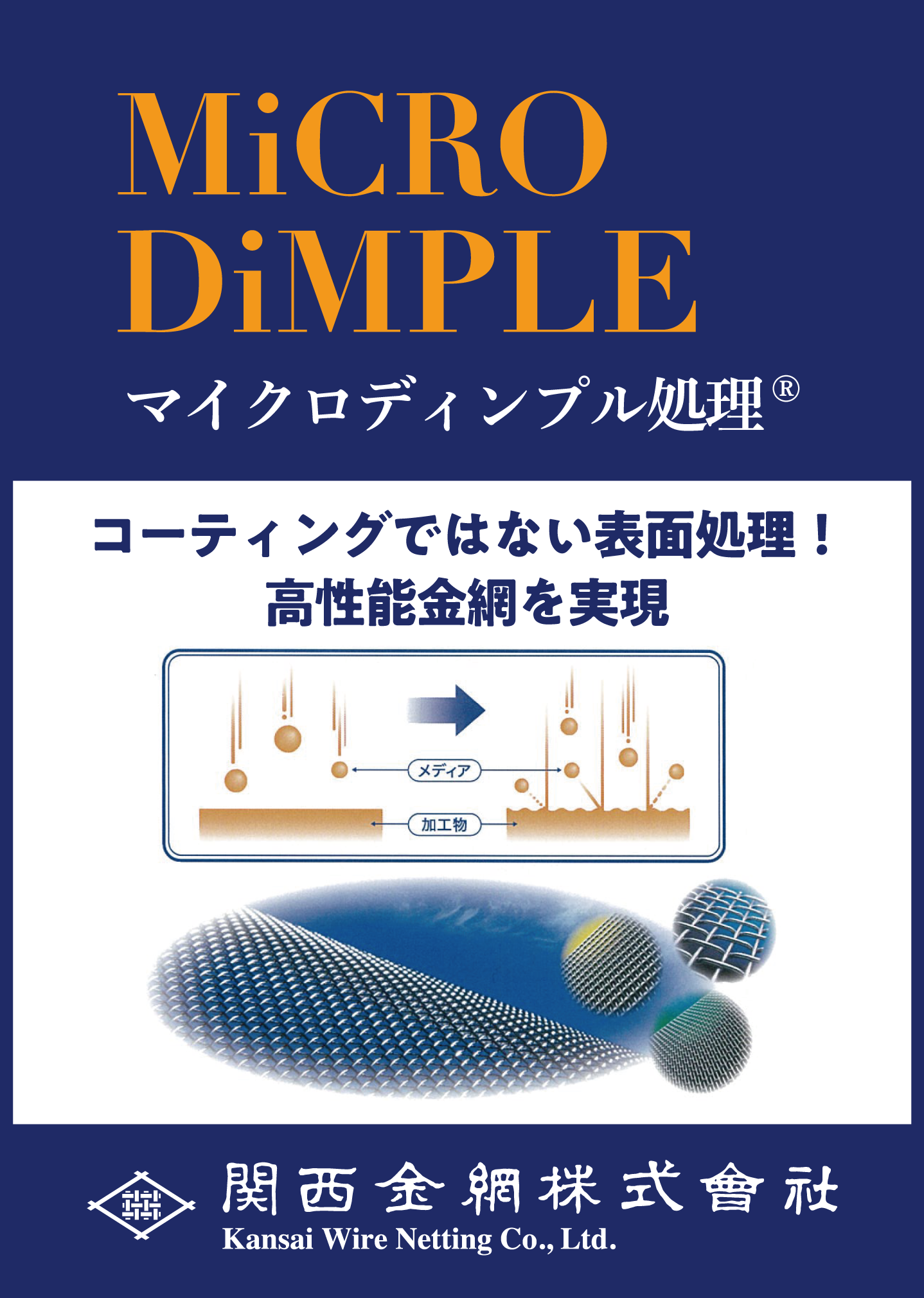

Surface treament not coated! Realizing high performance wire mesh.

Micro Dimple Processing®

What kind of product?

Micro Dimple Processing ® is a process in which fine media particles are shot on wire mesh or wire conveyor belt at ultra-high speed to create fine dimples on the surface. Controls indented surface according to type of powder/food and purpose. It improves the slipability of various transport items and reduces the adhesion clogging.

What's features?

・Higher non-stick property of transport materials

・Reduce adhesion clogging in sieving

・Dirt is easily removed

・No risk of contamination because there is no coat peeling off.

・Increase retention ability of oil in oven or fryer.

・Increase wear resistance by surface hardening.

What is actual effect!

Preventing foreign particle contamination!

In surface coating, there is a risk that the coating will come off during use and enter the product.

Micro dimple treatment® is not coated and does not come off.

It can be used safely witout worry.

Clogging suppression effect shortens processing time!

If you continue sieving with clogged wire mesh, it will take time to process. In some cases, micro dimple processing® shortens the processing time to 1/10, and in some cases, tapping balls used to prevent clogging are no longer needed.

Other things you wan to know

Q.Can you handle any material?

A.Any metal can be processed.

Especially good at stainless steel for food-related products.

Q.Stainless steel will not get rustted by this processing?

A.It does not.

Q.Certificate for safety can be issued?

A.Test report by official food test laboratory can be submitted.