Web Showroom

Support for various purposes!

End surface treatment of conveyor belt (edge processing)

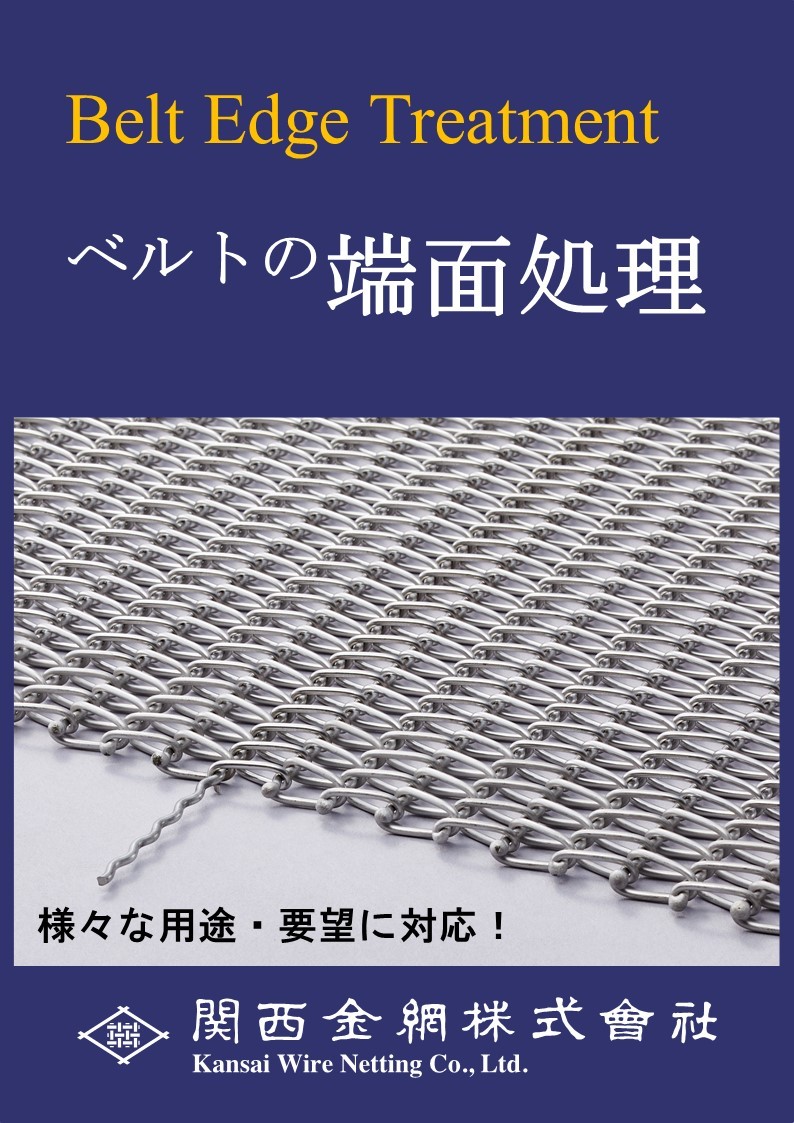

What is End Surface Treatment?

At the end of the conveyor belt, end surface treatment is required. The end surface treatment can be changed according to the application.

What kind of edge processing can you do?

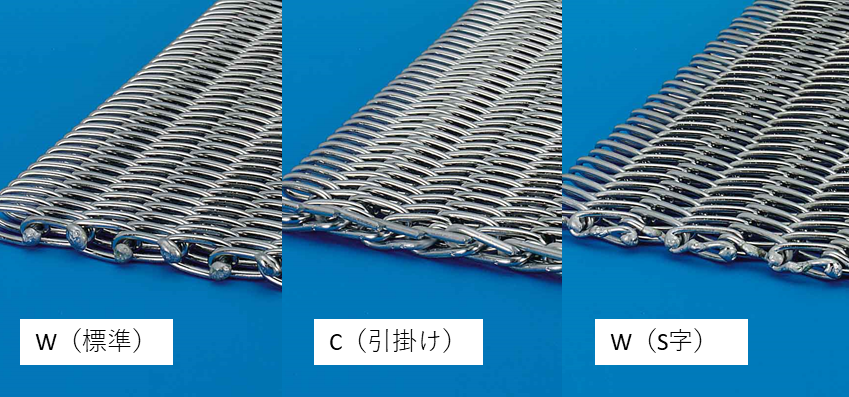

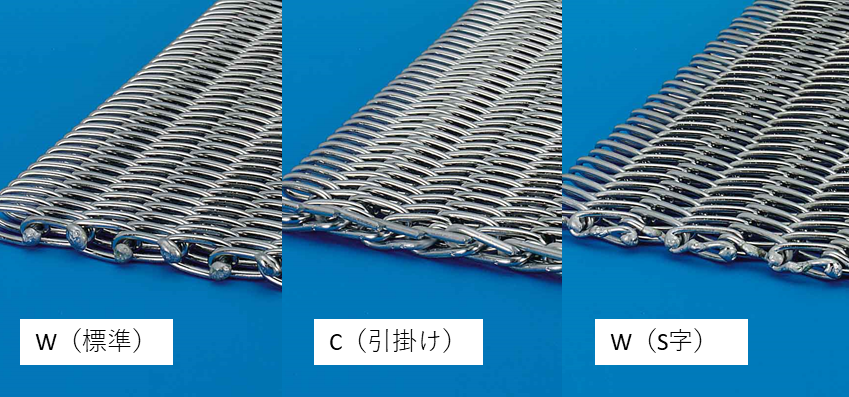

Basic end surface treatment

In order to prevent the rod from getting out of the spiral, fix the rod by welding/bending.

W (Standard): Welded spirals and rods, which are standard specifications.

C (hanging): The rod and the spiral are bent and hooked.

W (S): In A2W and K2W belts, spirals may be welded in S-shaped.

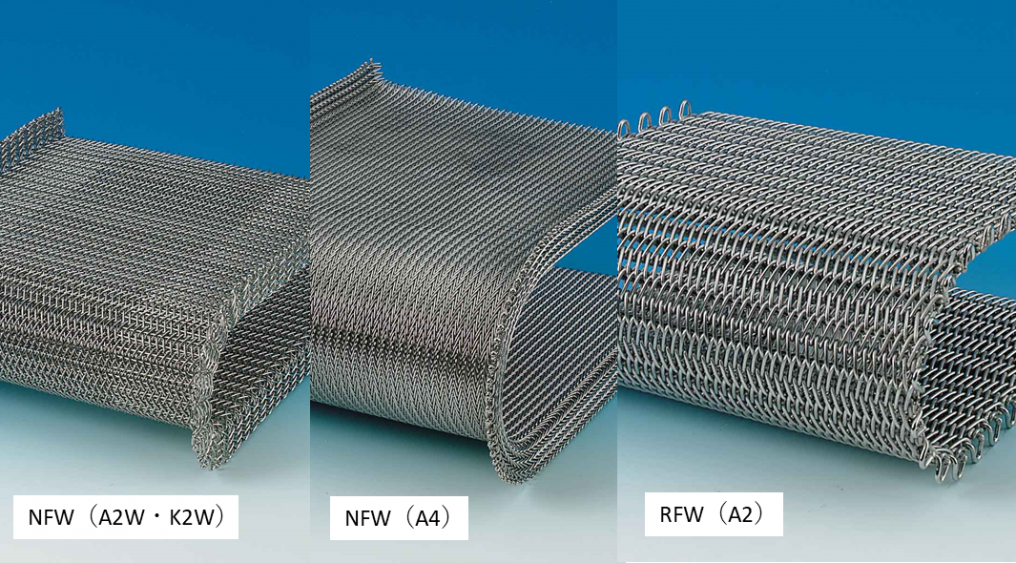

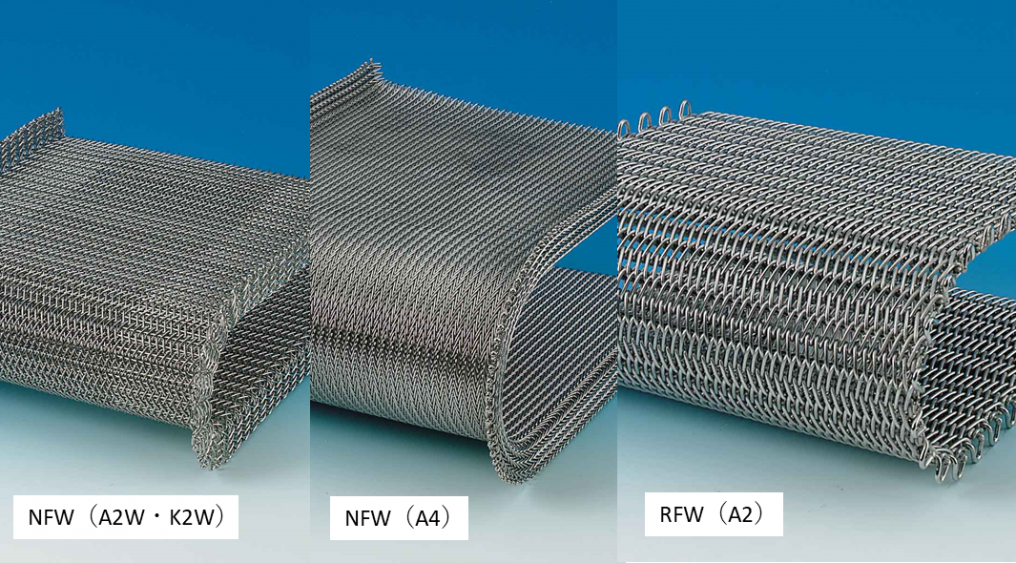

Net flange

The end of the belt can be folded and launched to prevent the product from spilling sideways.

There are some types that cannot be flanged. Please contact us for more information.

NFW(K2、A2、K2W、A2W): Insert a U-shaped skewer at the end.

NFW(A4): Welding is made every other and bended.

RFW: It is a type that welds rods bent in U-shaped.

With chain

Place a chain to a normal end surface treatment or a net-flanged belt. It is driven by sprocket and does not go diagonally.

Plate flange type: Incorporate a high chain plate to prevent the product from spilling sideways.