Technical Information

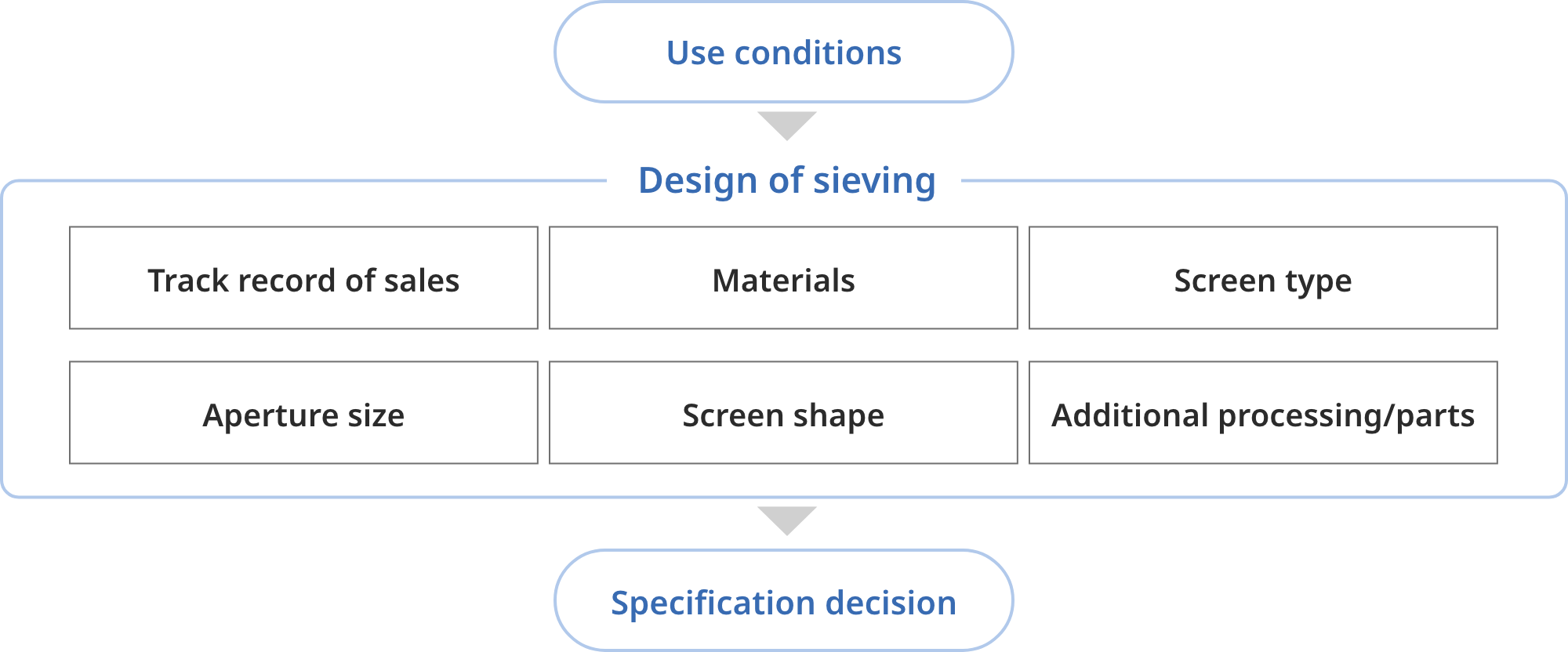

Design Flow

Kansai Wire Netting proposes optimal sieve-sieve screens (sieve-sieve-sieve wire mesh) based on customer's usage conditions.

Design Flow

| Operating Conditions | Check the particle characteristics and operating conditions of the process of installing or using the screen. |

|---|---|

| Experiences | If you are already using a screen, or if our experience in the past matches the operating conditions, we will refer to them. |

| Material |

Select the material in consideration of temperature, corrosion environmental, magnetic necessity and strength. To KMG Mesh |

| Screen Type |

Select the screen type (type of wire mesh) based on the purpose and usage conditions of the sieve. For details on each screen type, see Product Information. To Screen Selection Flow Example |

| Aperture size |

Calculate the aperture size of mesh screen from the particle size you want to separate. Open area is also determined based on the balance between processing capacity and strength of mesh screen. To Aperture Size・Open Area Calculation |

| Screen Shape | Determine the screen shape (circular, rectanglar, etc.) according to the sieving machine used. |

| Additional Processing and Parts Examples |

If necessary, reinforce and protect the screen and add clogging measures. Additional processing and parts examples |

| Determing Specification | After the above design, we will determine the screen specifications that meet your needs. |

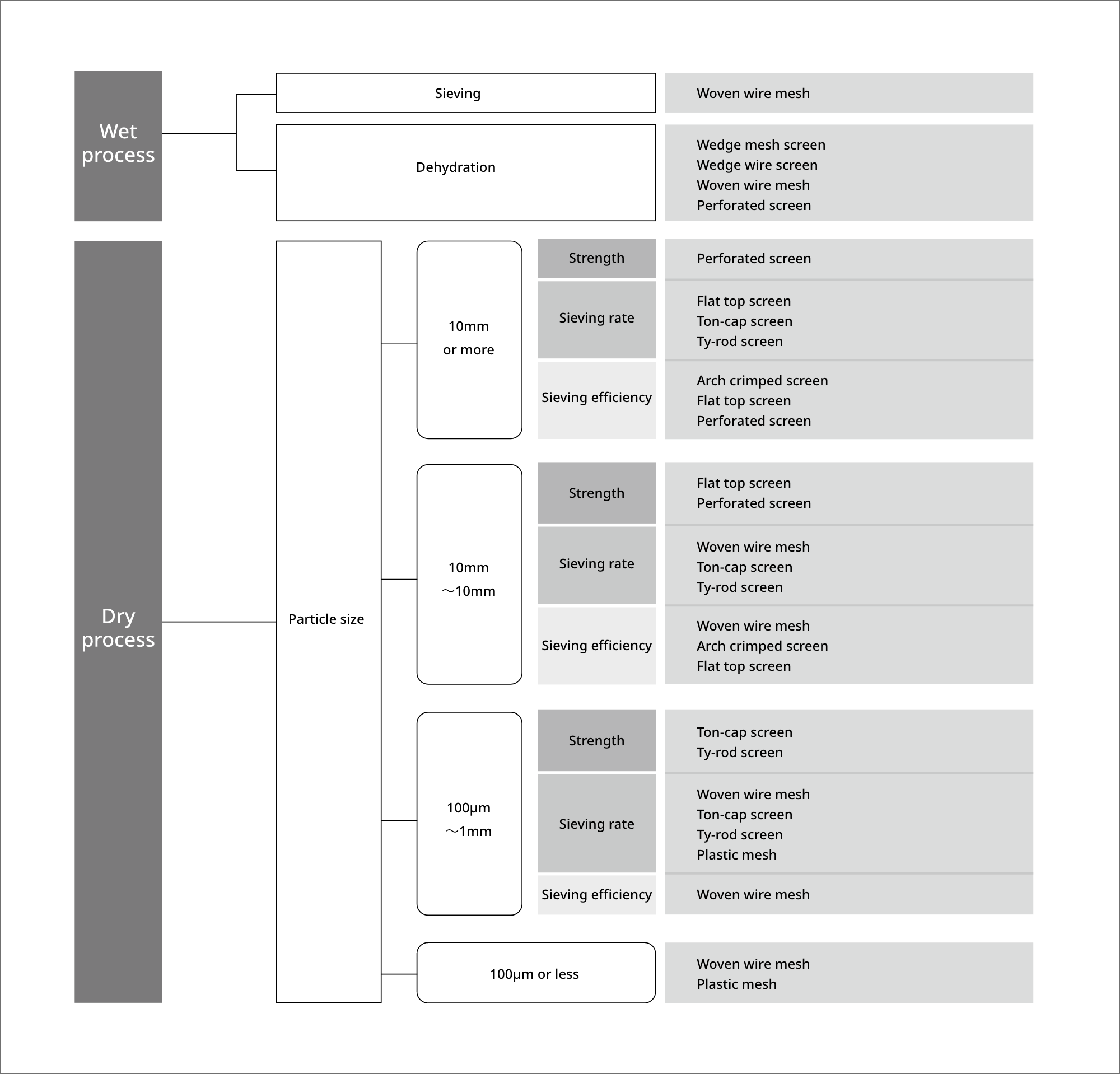

Screen Selection Flow Example※

※This flow is only a guide and may differ from the actual one.

We can accommodate custom orders!

There are a wide variety of industrial wire mesh depending on customer's application and operating conditions. Our products are made to order in cooperation with each department to meet customer needs.

From hearings to support after delivery, we provide the optimal products that customers demand through an integrated system.

KMG Mesh®

Austenite stainless steel, such as SUS 304 which is widely used in woven wire mesh, has poor magnetic properties and is difficult to detect and collect a piece of wire even if the screen is broken. On the other hand, there are ferrite and duplex stainless steel with magnetic properties, but those in market have pooer corrosion resistance or difficult to weave for wire mesh.

KMG Mesh® developed by us has overcome the above weakness and is widely used as countermeasure against foreign particle contamination.

KMG Mesh® has the following two types of magnetic materials.

1. KNM21

Suitable for application that requires strong magnetic woven wire mesh.

Applicable wire diameter φ0.1mm or more, max mesh: 100mesh

2. Durmalloy

Suitable for application, which requires magnetic and durable woven wire mesh.

● Dermaloy I (for details) ... Applicable line diameter: φ0.6mm or less, maximum mesh: 400mesh

● Dermaloy II (for rough) ... Applicable line diameter: Maximum mesh exceeding φ0.6mm: 12mesh

Both can be processed into various screen shapes like normal woven wire mesh. Please see the screen catalog for details of KMG mesh.

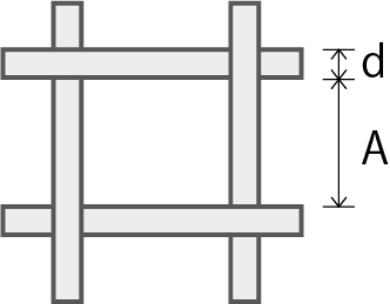

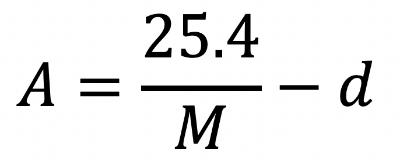

Calculation for Aperture Size/Open Area

Aperture size of plain weave and twilled weave mesh can be calculated by the following formula.

A: Eye opening [mm] M: Mesh [-] d: Line diameter [mm]

Mesh refers to the number of wire lines or apertures between 1 inch( 25.4 mm ). For example, a 500 mesh wire mesh contains as many as 500 metal wires per inch.

From this formula, it can be seen that Plain weave Twilled weave cannot be identified by mesh or aperture size alone, and at least two of wire diameter, Mesh and aperture size are required.

Example: “100mesh” does not determine the opening of the eye, and “100mesh with a line diameter of 0.1 mm” will be “eye opening 0.154 mm” and “line diameter of 0.12 mm” will be “eye opening 0.134 mm” at 100 mesh.

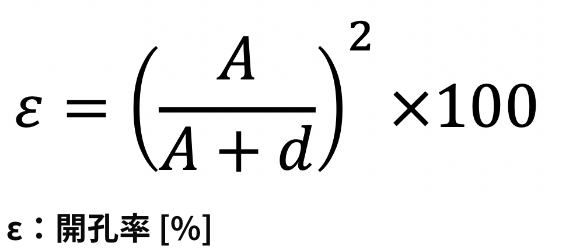

The opening rate (the ratio of the area occupied by the mesh opening of the screen surface) is calculated by the following formula.

In the case of the same aperture size, the smaller the wire diameter, the higher the open area and the higher the processing capacity, but the lower the strength. Conversely, if the wire diameter is enlarged in the same aperture size, the open area will be lower and the processing capacity will be lower, but the strength will increase.

The catalog also has a list of specifications that summarize the relationship between Plain weave, Twilled weave's wire diameter, aperture size and open area.

Please refer to the product information and catalog for other screen types, such as punching metal (punched wire mesh).

Plain dutch/Twilled dutch weave has a 3-dimensional aperture structure, so calculation of pore size is complicated. If you need pore size calculation, pleae contact us.

Please do not hesitate to contact us

If you have any other technical issues or questions,

please do not hesitate to contact us.

Additional Processing and Parts

In consideration of usage conditions and past trouble cases, we will perform the following additional processing and attach additional parts as necessary.

- Weld the wire mesh edges at appropriate intervals to prevent the wires from fraying.

- Protect and reinforce with plastic(silicon, etc.) the area where screen contacts with support bar of sieve machine.

- Fluorinated resin or Micro Dimple Treatment® is performed to control powder adhesion and clogging.

- A reinforcement plate will be installed to protect the powder input area. Etc.

※Micro Dimple Treatment®is a registered trademark of Surf Technology Co., LTd.

Trouble-shooting of Wire Mesh

Various problems may arise in sieving.

Clogging( single clogging, collective clogging, adhering clogging, etc.) and the following typical problems and their solutions are listed in the catalog.

- Torn the wire mesh

- Wire mesh is worn and broken by abrasion

- The same place always breaks.

- Increasing capacity of processing

- Increaseing sieving efficiency

Sifting screen

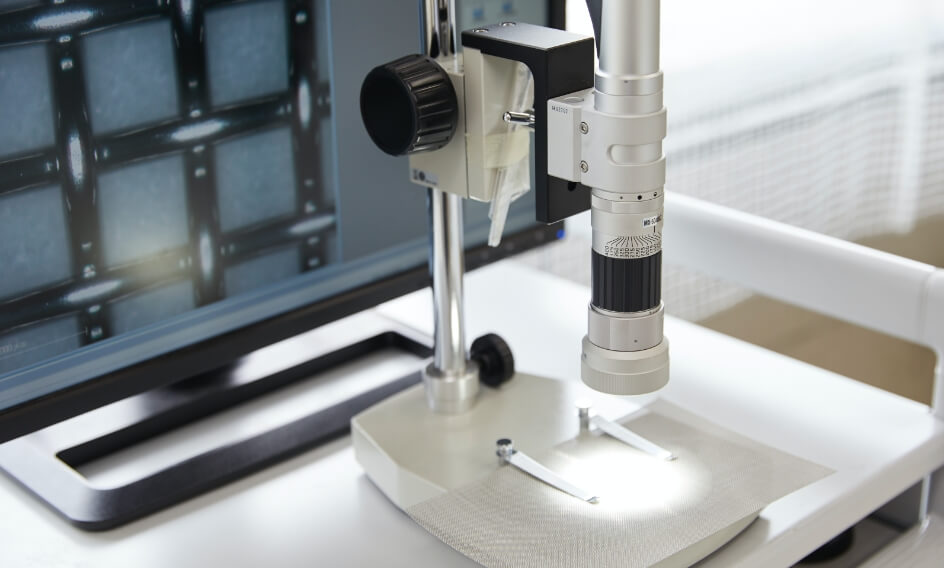

Evaluation test

In the design and developent of screen, aperture size, strength and sieving performance are evaluated as necessary. Therefore, we have a variety of testing facilities. Structural analysis may also be performed to evaluate strength.