Web Showroom

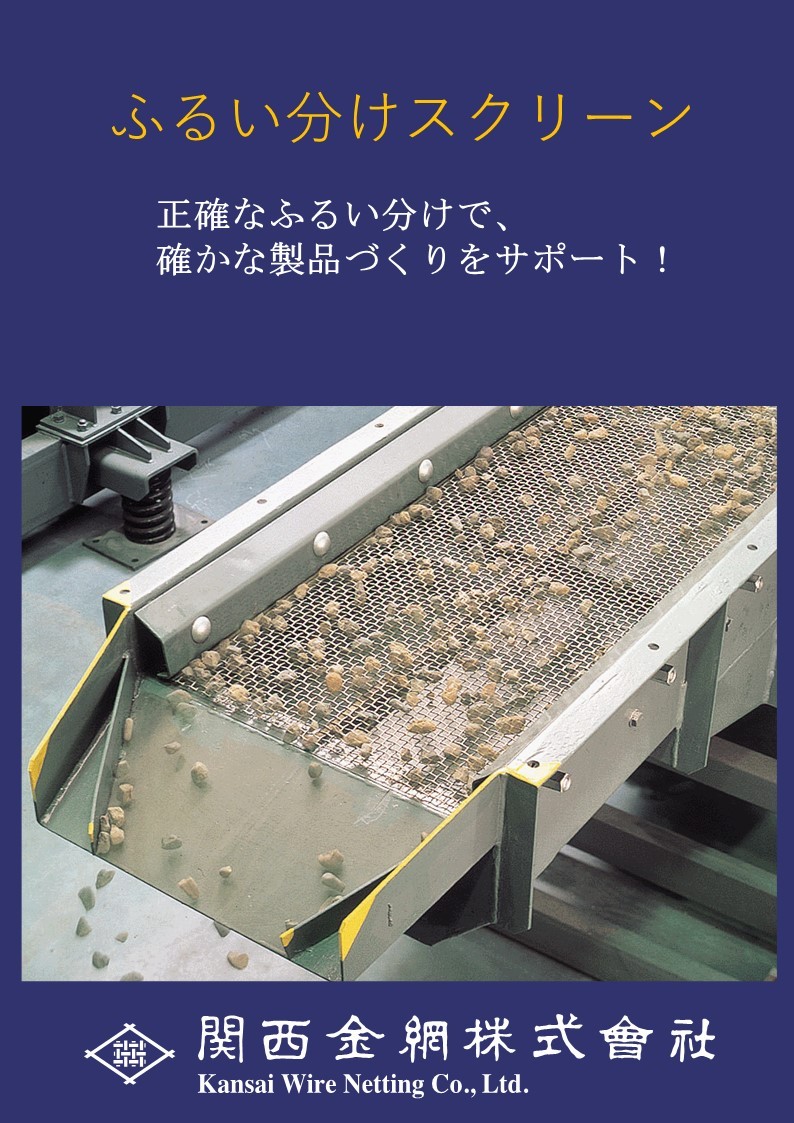

Supporting the creation of reliable products with accurate sieving

Screen

What kind of product?

sieving is an operation that divides into a group of particles passing through the aperture on the screen (wire mesh) and a group of particles not passing. Since individual particles are checked against mesh aperture size, reliable and accurate separation is possible, making it indispensable for powder-related industries.

Example of use.

Food: Classification, scalping and removing foreign material for food powder such as sugar, salt, flour and starch powder

Civil Engineering: Classification for quarrying, sand, wood chips and cement

Environment: Separation and classificaton for surplas soil, industrial waste and waste plastic

Machinery: Clasiffication of abrasives and blasting material

Pharmaceutical Classification for raw material powder, granule and powdered medicine

Chemistry: Classification for row material/removing foreign material for raw material. Classification /collection for powder chemical powder.

Steel: Classification for iron powder, coke and slag

Electronics: Classification for toner raw material and battery materials

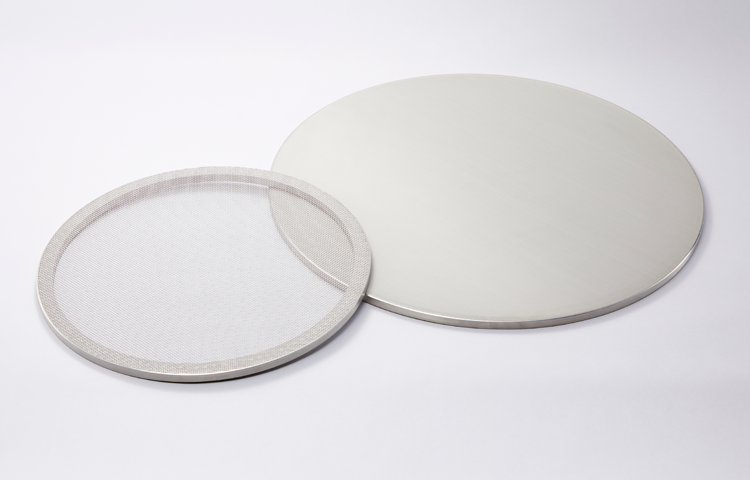

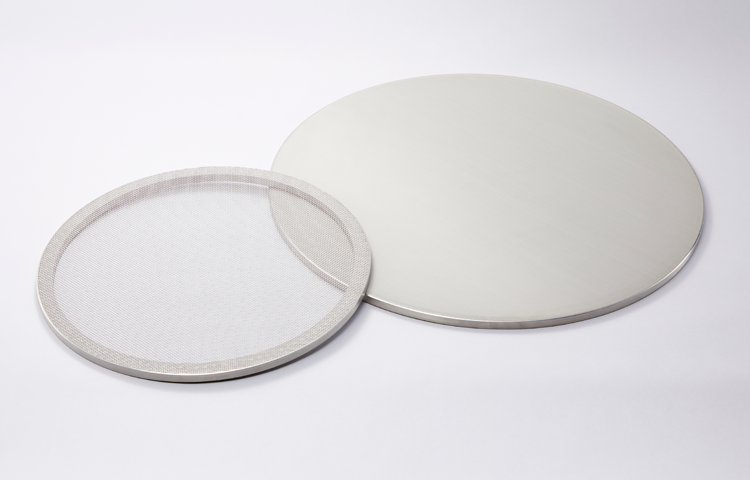

Circular Screen

Screen used for circular vibration sieves and ultrasonic sieves.

Depending on the sieve machine, there is a type that directly mounts the screen, and a carftridge type that mount the screen on a special frame in advance.

The direct mounting type can replace the screen at low cost, but high technology is required to install it with an appropriate tension.

As for the cartridge type, it is easy to replace screen because you only set screen fixed on the special frame in advance with an appropriate tension on the sieve machine, but it is more costly than direct mounting type. In the cartridge type, the screen is fixed to the dedicated frame with adhesive (bonding), soldering, continuous spot welding, seam welding.

Square-shaped sieve

Screen used for rectanglar's vibration sieve machine. In case of using screen with rectangular mesh aperture(slot), be careful for direction of slot against flow direction of powder. Depending on the sieve machine, there are screen with Tension Hook that is fixed and tensioned by clamping bars on the sieve sides, and cartridge type that screen is fixed on special frame. Our Tension Hook standard specifications can be broadly divided into seven types (HOOK No.1-7), which can be used according to screen specifications and sieving conditions. Other hooks include a hook shape with a flat bar or angle screen fixed.

Others

Test Sieve is a framed wire mesh mainly used to measure particle size distribution. Very high eye opening accuracy is required for test sieves (JIS Z 8801-1), and carefully selected wire mesh is used. There are many other sieves and screen. For example, in the above screen introduction, the sieving machine that shift powders by vibration was mentioned, but there is also air classifier with a circular screen. Large round or hexagonal shaped cylinder screen is used for rotary screen called trommel. Mogensen sizer is a sieve machine with steeply declining multiple screen decks. Separation point is controled not oly by mesh aperture size but also by angle at which particle enters aperture.