Products

- From category and application

Search - From Challenges

Search NEW

- Selected

- Environmental

- Search Results

- Displays 19/1 to 19

-

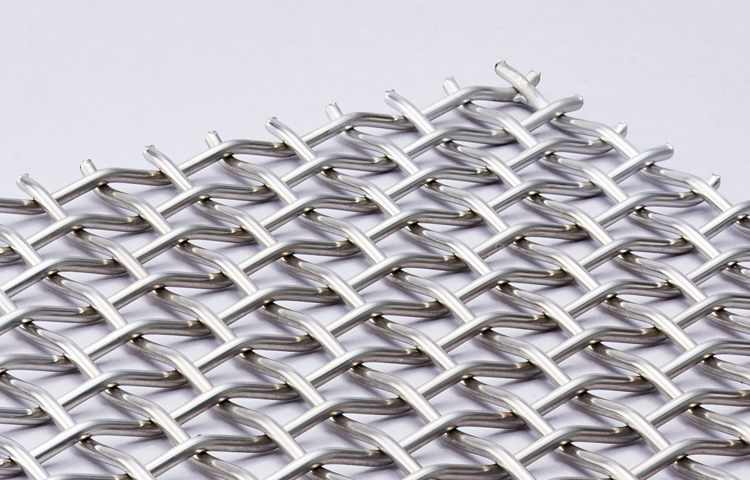

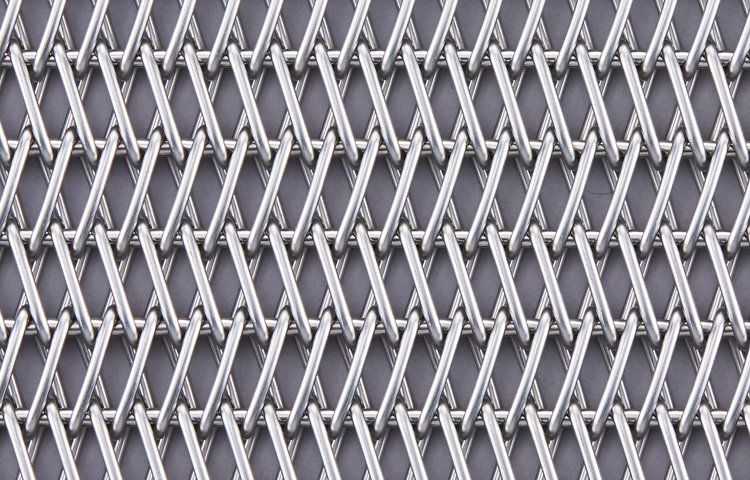

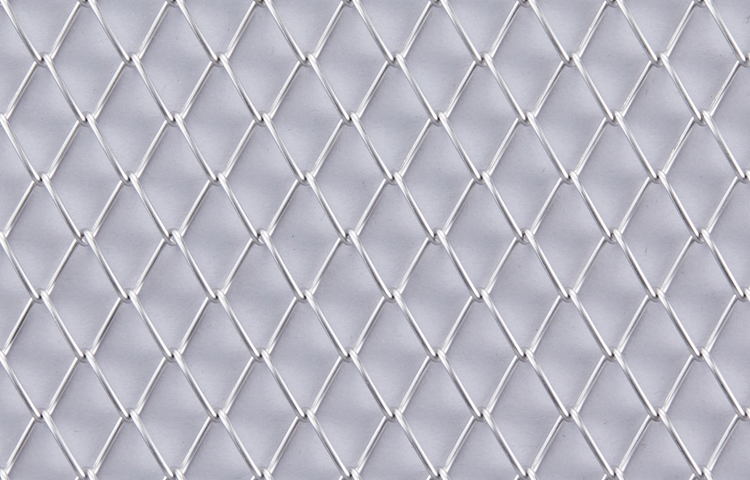

WOVEN WIRE MESH(FOR SIEVING APPLICATIONS)

We can offer a wide range of specification for various applications

see the details -

PRE CRIMPED SCREEN

It is made with wires that have been crimped prior to the final weaving process.

・Thick wires can be used for aperture.

・Stable opening

・High opening ratiosee the details -

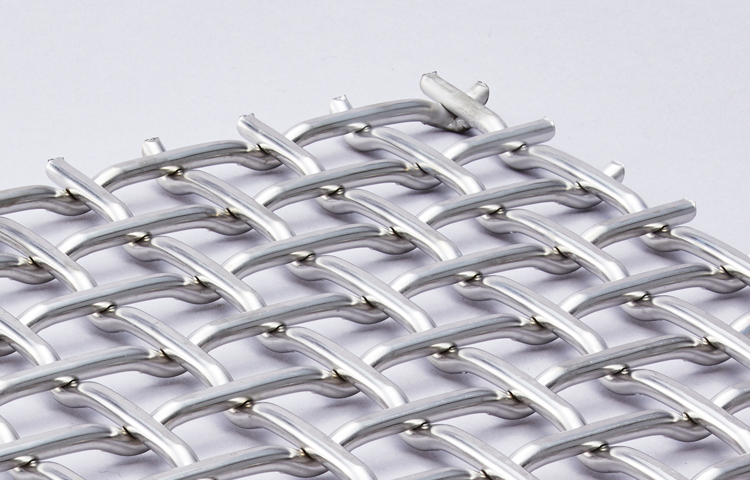

FLAT TOP SCREEN

One side of the mesh has flat surface ,which provides smooth flow of powder.

see the details -

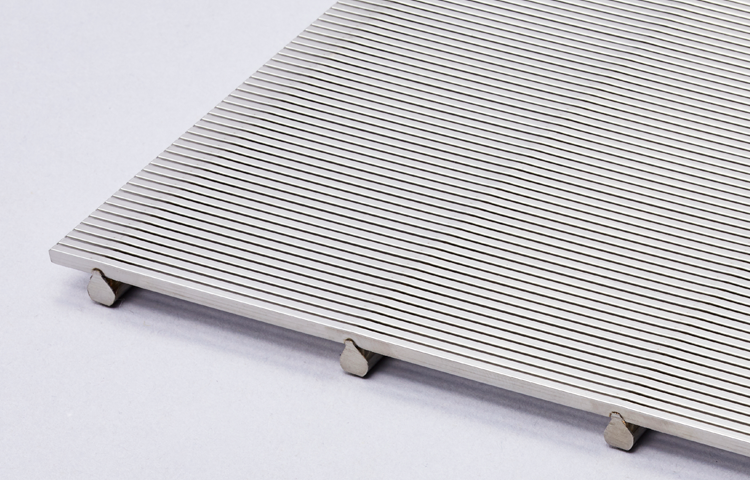

WEDGE WIRE SCREEN

It is hard to get clogged even with a small slot. Useful for various applications.

see the details -

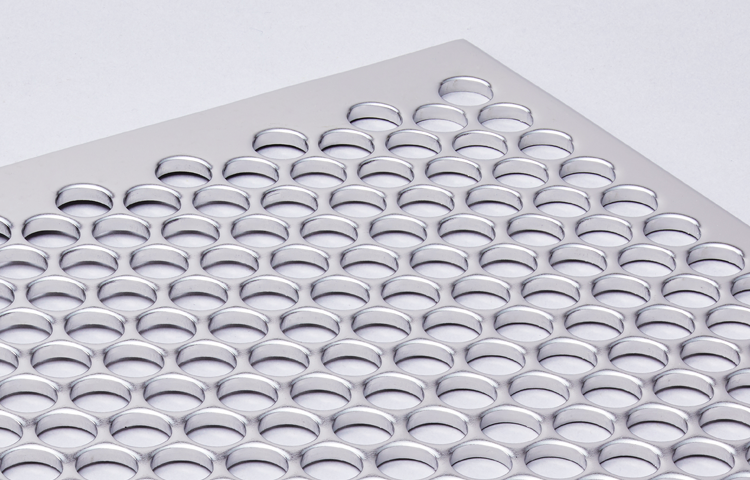

PERFORATED SCREEN

Perforated screen has stable opening and enough strength because it' made of metal sheet.

It can be punched on materials such as iron plates, high tension steel plates, stainless steel plates, etc. in the shape of round holes, square holes, and long holes.

Processing such as with tension hooks and cylindrical shape is also possible.

It is used in a wide range of applications, including vibration sieves, filters that filter liquids such as water, and rectifications that control the flow of gas.see the details -

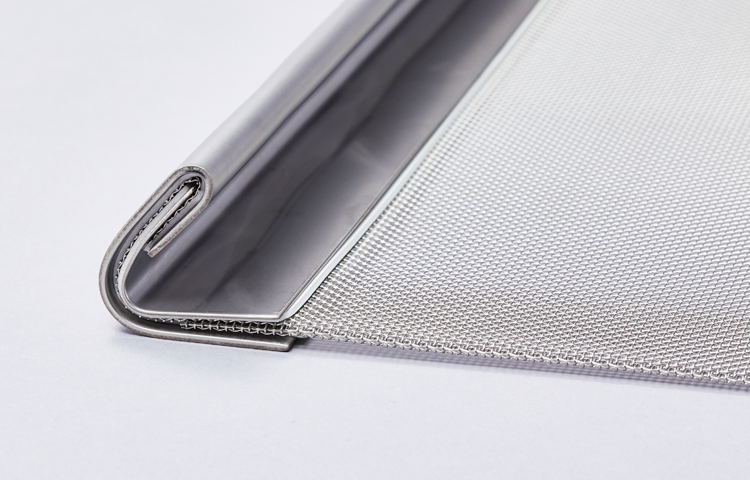

TENSION HOOK

By attaching tension hooks to the wire mesh, it is possible to use it for vibration sieve machines such as square shifters.

see the details -

TEST SIEVES

"Test Sieve" is used for particle size distribution measurement and the accuracy of aperture size is very important. Under stringent quality control, we meticulously choose materials and weave wire mesh using high-precision, specialized weaving looms.

All finished wire meshes undergo a comprehensive inspection following the JIS Z8801-1 (Test sieves - Metal wire sieves) standards. Only those that meet the required standards are approved for shipment. The inspection data can be provided as our internal inspection report. Additionally, Inspection certificate by JQA (Japan Quality Assurance Organization,nominated by the Ministry of Economy, Tradeby ) can also be provided.

see the details -

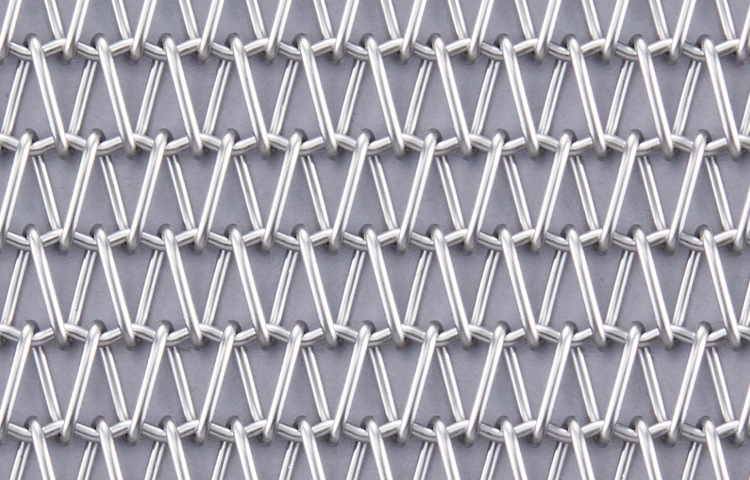

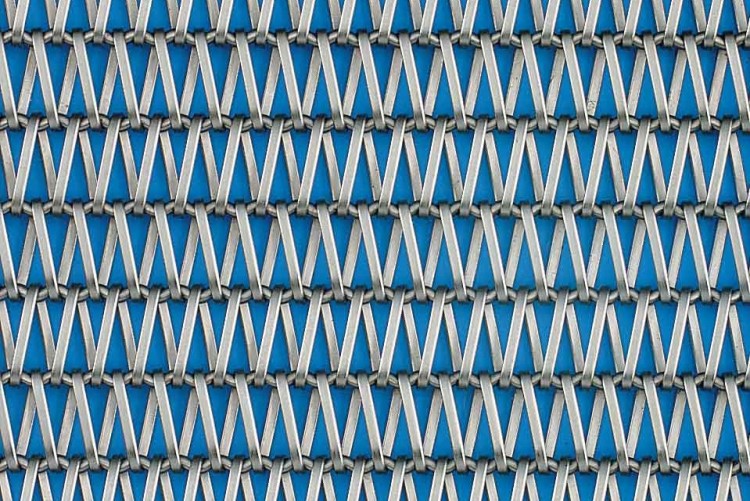

K2

Spirals of left wound and right wound are alternatively assembled and connected by crimped rod.

see the details -

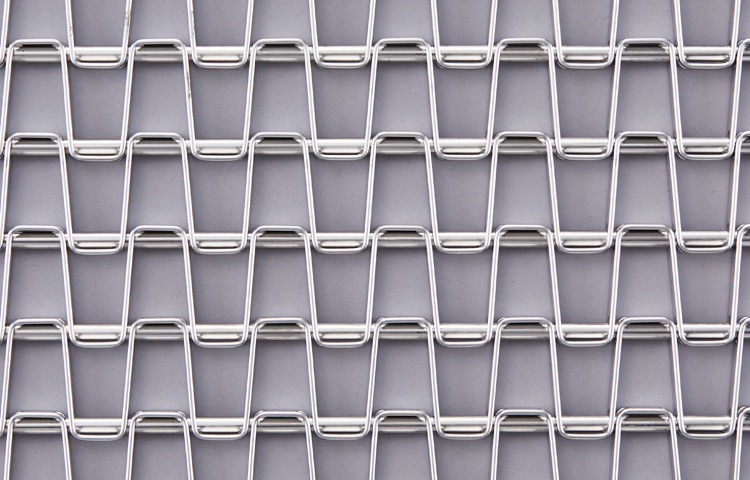

F2・A2

Spirals of left wound and right wound are alternatively assembled and connected by straight rod. A2 with rod pitch less than twice spiral pitch. F2 with rod pitch more than twice.

see the details -

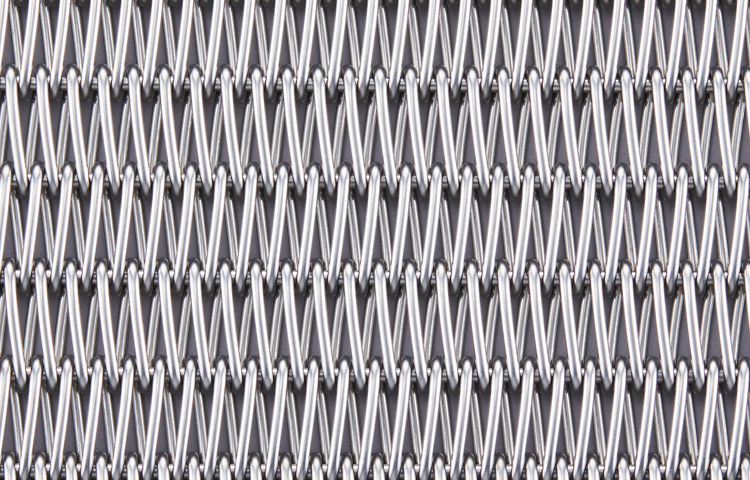

K2W・A2W

K2W is double spirals type of K2 and A2W is that of A2.

see the details -

S

Spiral type with one winding direction.

see the details -

FW

Flat wire is continuously processed into grid and connected by straight rod.

see the details -

CHAIN DRIVEN CONVEYOR BELT

Chain attached on both sides of normal wire conveyor belt. Belt and chain are matched by stay pin.

see the details -

SPECIAL TYPE

KF2 and AF2 types use flat wire as spirals. A3W type has narrower gap by inserting one more straight rod than A2W type.

see the details -

WOVEN WIRE MESH(FOR FILTER)

The fundamentals of filtlation and the origins of filters

see the details -

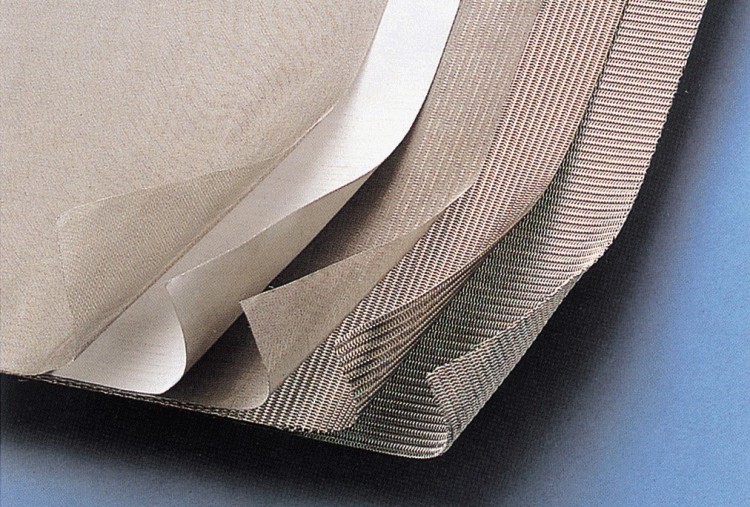

SINTERED WOVEN WIRE MESH

Various wire meshes are laminated and sintered together using our unique sintering technology.

The ideal filtration structure is achieved through multilayer sintering.

see the details -

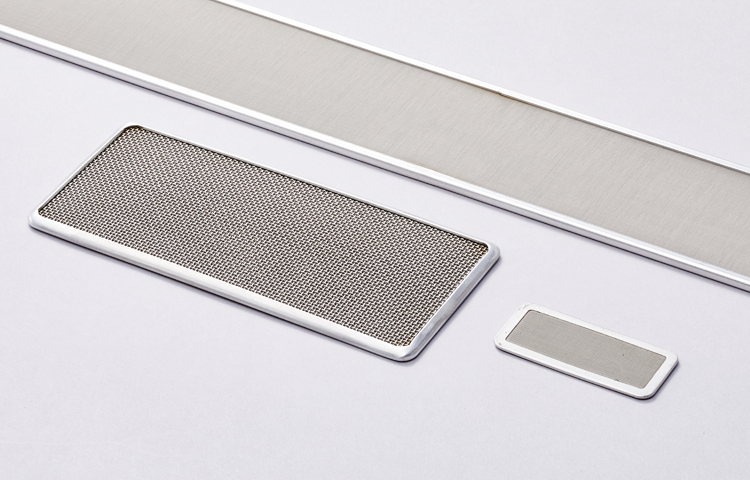

BONMESH STRAINER

It is a strainer of stainless steel ,in which wire mesh and perforated screen are sintered together. It is the most suitable for manufacturing processes of foods and pharmaceuticals , which needs to meet standards of HACCP and GMP because hygienic safty and cntamination-free are required.

see the details -

WIRE MESH MIST ELIMINATOR

Wire Mesh Mist Eliminator is a complex structure formed by layering thin-knitted wire mesh pads. Each pad consists of two knitted wire mesh sheets that are alternately waved and stacked in multiple layers.

Since it has very high opening ratio (94%~99%), its weight is very light, the surface area is very large and the pressure loss is very low.see the details -

BASKET

Wire mesh can be processed into various shapes.

We can customize the product according to your desired shape.see the details